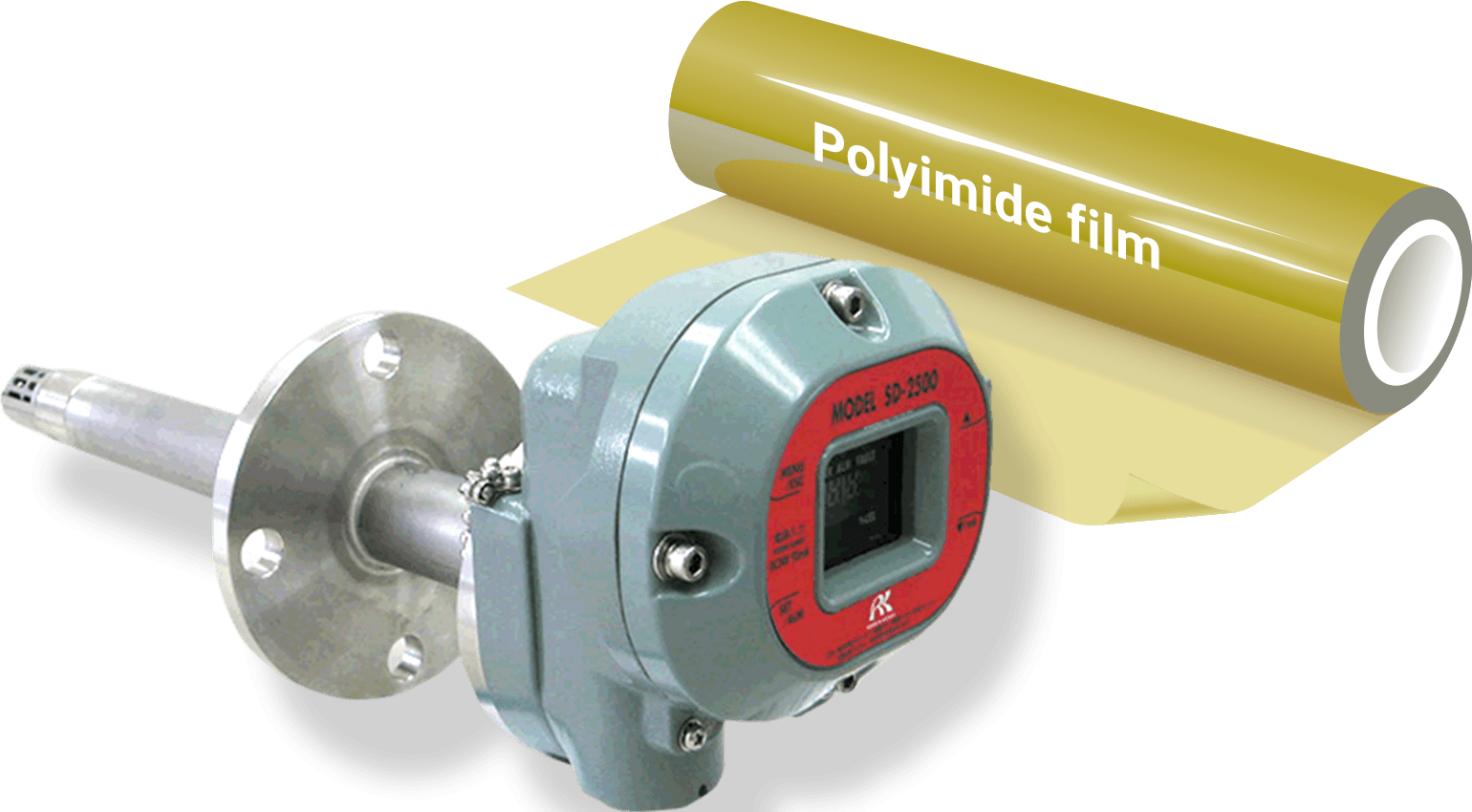

Gas measurement for high boiling point solvent drying equipment

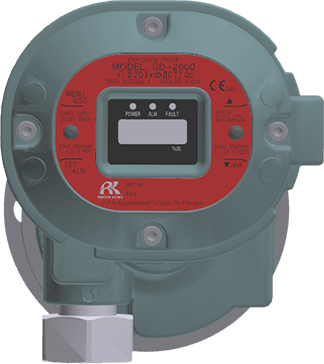

Explosion-proof Furnace Safety Monitor

SD-2600

-

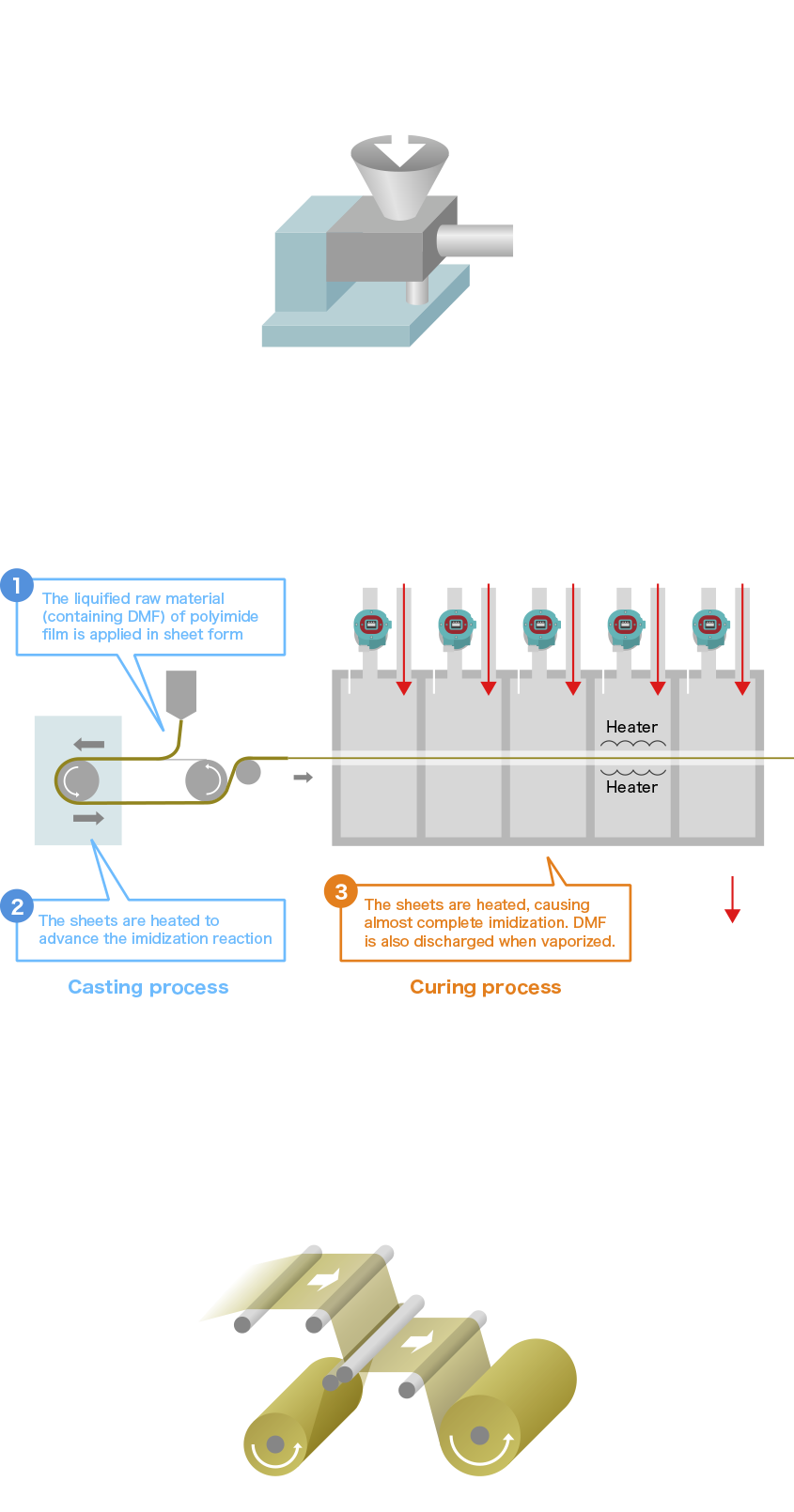

DMF detection

-

Explosion-proof

-

Direct insertion

into furnace -

Low Maintenance

Cost -

Global Standard

Approved

Product Features

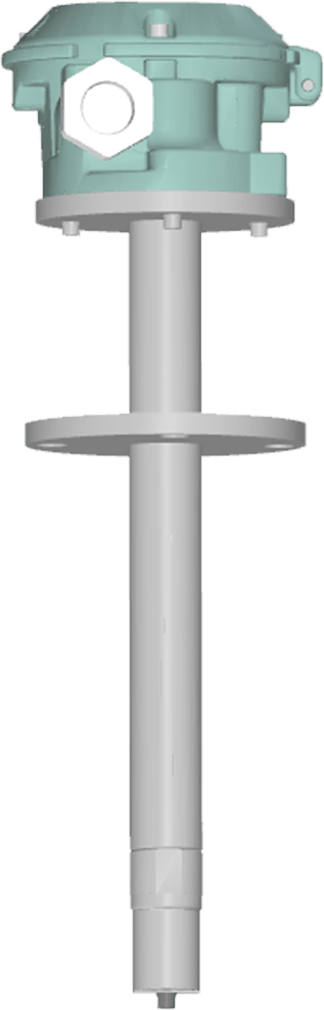

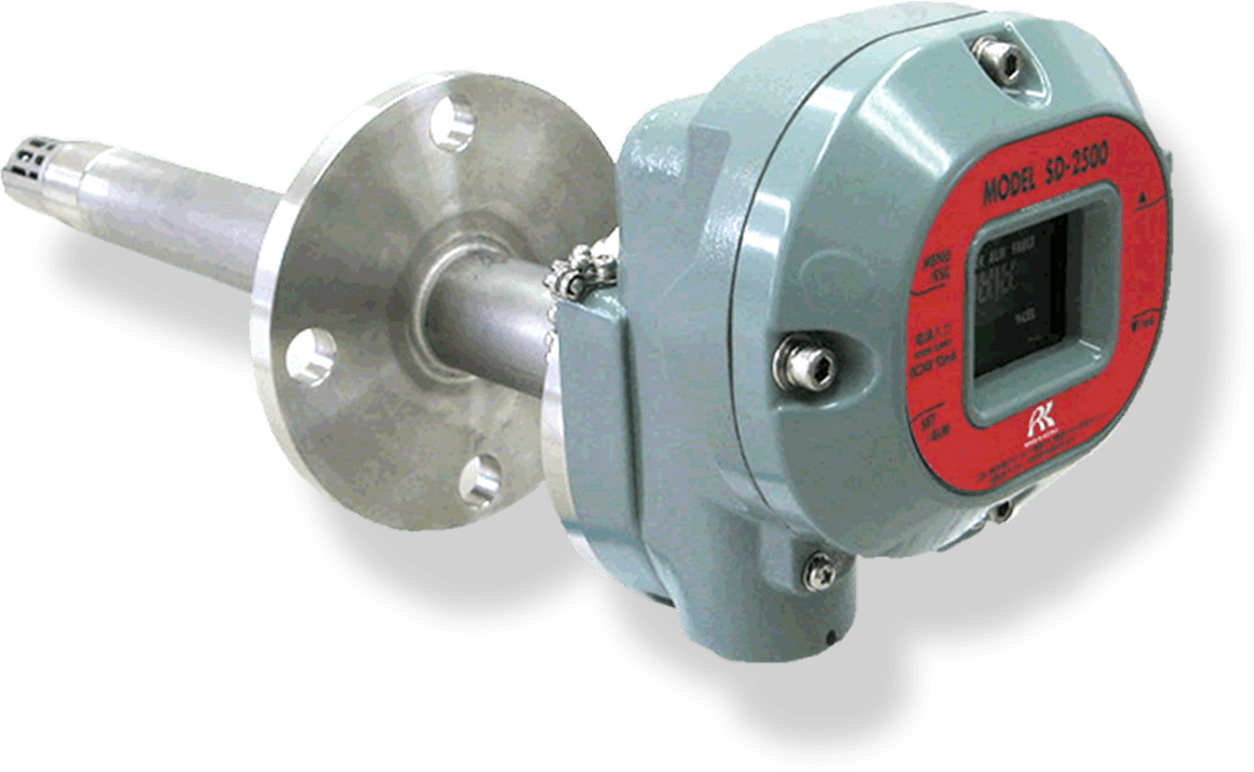

Direct insertion type fixed gas detector with explosion-proof structure and robustness

Explosion-proof, direct-insertion type sensor, can withstand temperatures of up to 200°C

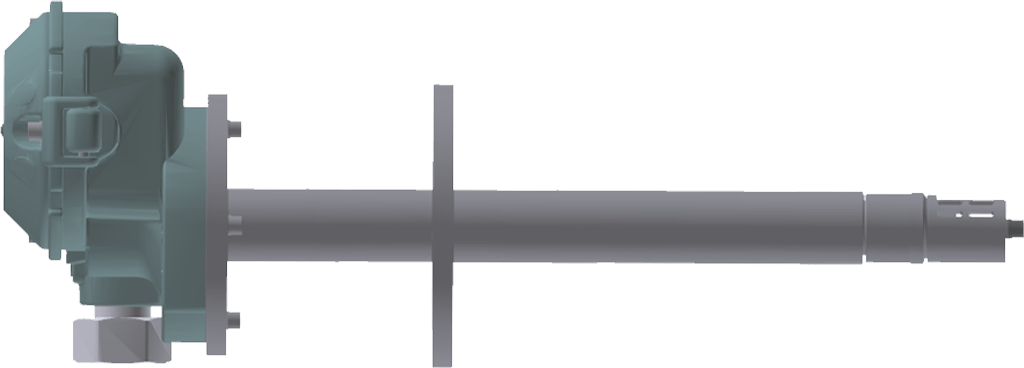

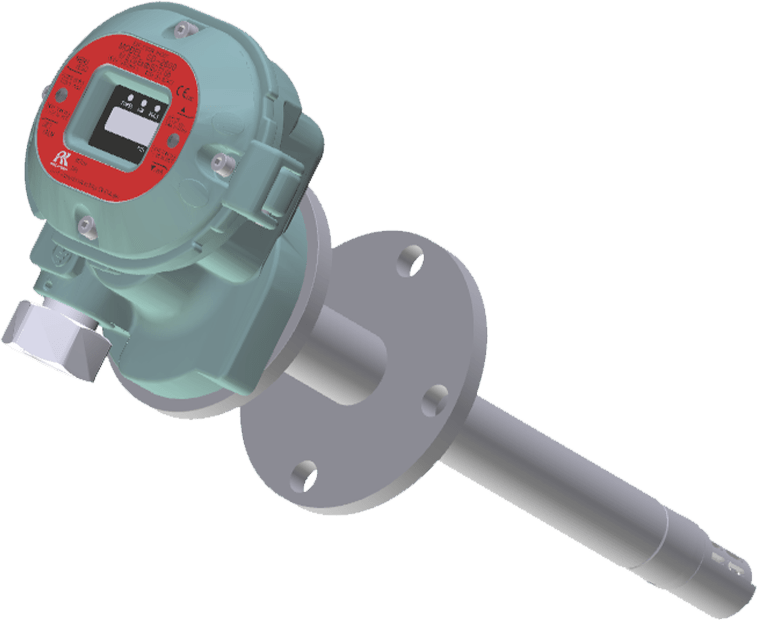

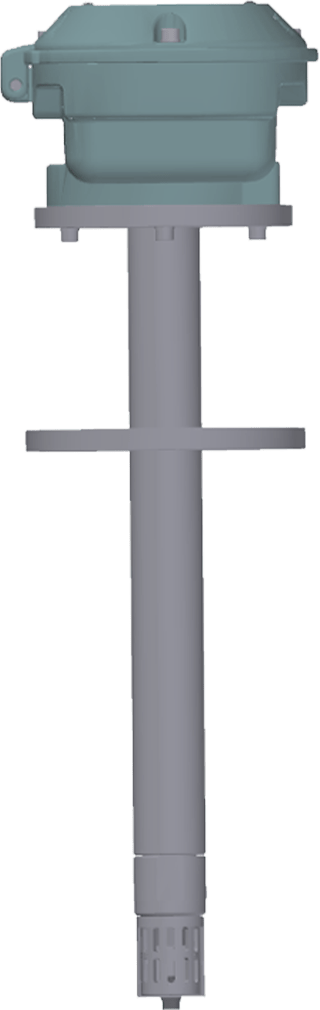

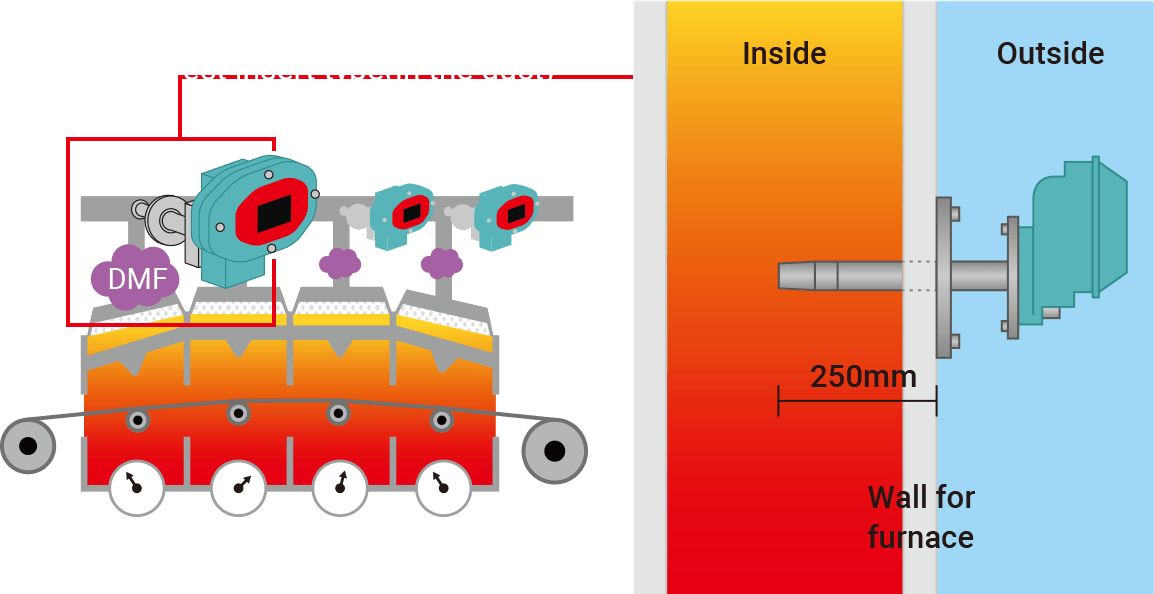

Furnace direct-insertion type sensor, accurately catches concentrations in the central part of the exhaust duct.

Enables detection of true values inside furnaces which cannot be measured by sampling, such as for high boiling-point solvents. (Operating temperature range: 0–200℃)

Easy for maintenance with the indicator and the detector combined structure.

Smart type design with the main body (detector) and display section

(indicator) combined. No need for a seperated indicator unit.

Various functions meet the customers' needs

Self-diagnosis function

Gas concentration and configurable alarm contact output available. Self-diagnosis function is also available so that it can be used for kiln control without anxiety.

Simple operation

Simple operation! Only use a magnetic key to touch the panel.

Easy installation

Flange-type installation makes it easy to consider installing. Sensor is installed by modifying existing furnaces, eliminating the need for built-in sensors. Actual installation is also very easy.

Combustible Gas Monitoring Comparison

| Company | RIKEN KEIKI | Company A | Company B | Company C |

|---|---|---|---|---|

| Insertion depth | 250mm | 250mm | Not Available | 250mm |

| Operating temperature(Sensor) | 0℃ ~ +200℃ | -20℃ ~ +80℃ | -40℃ ~ +150℃ | 0℃ ~ +160℃ |

| ATEX / IECEx / UL | Acquired | Acquired | Acquired | Not Available |

-

Insertion depth

- RIKEN KEIKI

- 0~200℃

- Company A

- 250mm

- Company B

- Not Available

- Company C

- 250mm

-

Operating temperature (Sensor)

- RIKEN KEIKI

- 0℃ ~ +200℃

- Company A

- -20℃ ~ +80℃

- Company B

- -40℃ ~ +150℃

- Company C

- 0℃ ~ +160℃

-

ATEX / IECEx/ UL

- RIKEN KEIKI

- Acquired

- Company A

- Acquired

- Company B

- Acquired

- Company C

- Not Available

Customer Feedback

Many customers use Riken Keiki's gas detectors

due to our safety, and high-level product

development capabilities.

Product

Specifications

- Detection method

- Duct insertion, Direct insertion type in furnace

- Principle of detection

- Catalytic Combustion Method

- Detection range

- 0 to 100%LEL

- Type of alarm

- Gas alarm / fault alarm

- Explosion proof type

- Flameproof enclosures

- Explosion-proof class

- IECEx : Ex db IIC T2 Gb ATEX : II2G Ex db IIC T2 Gb

- Approvals

- Japan Ex, ATEX, IECEx, UL

- CE marking

- EMC / ATEX / RoHs

- Power supply

- 24 VDC±10 %

- Dimensions

- Main body : Approx. 148 (W) x 167 (H) x 458 (D) mm

Insert part : Approx. φ34 x 250 mm

- Weight

- Approx. 4.6 kg

- Operating temperature range

- Insert part: 0 to 200 ℃ (no sudden changes)

Main body: 0 to 50 ℃ (no sudden changes)

- Target gas

- 2,4-pent, 2-EHM, Benz-ol, C10H16, C10H18, C10H22, C11H24, C12H24O3, C12H26, C14H30, C2H2, C2H4, C2H4O2, C2H5OH, C2H6O2, C2H7NO, C2H8N2, C3H3N, C3H6O, C3H6O2, C3H6O3, C3H8, C3H8O, C3H8O2, C4H10O2, C4H10O3, C4H12N2, C5H4O2, C5H6O2, C5H8, C5H8O, C6H10O, C6H10O3, C6H12, C6H12O2, C6H12O3, C6H14O2, C6H14O3, C6H5OH, C7H14O, C7H16O3, C7H8, C8H10, C8H16, C8H16O2, C8H8, C9H12, C9H14O, C9H18O, CH3OH, CO, Cumene, DBuE, DEGEE, DMAC, DMEA, DMF, DMI, DOP, EGDME, EtAc, H2, i-C4H10, i-C7H16, iC12H26, IPA, iPenOAc, KEROSEN, LAE, MAA, MEK, MeOAc, MIBK, MMA, n-BMA, n-BuOH, n-C4H10, n-C5H12, n-C6H14, n-C7H16, NAPHTHA, NMP, OCTYLAc, PC, PGLY, PGMMEAc, TBA, THF

For other solvents, please contact us.

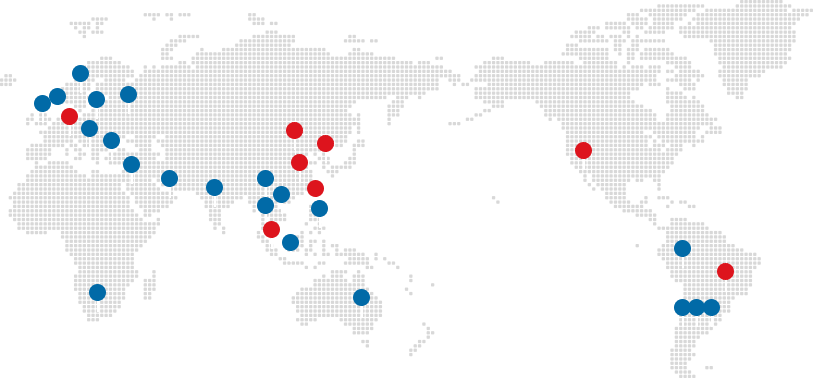

Extensive international network

for reliable and complete support

Utilizing our established overseas network, you

could purchase our product and services all over

the world.

- Affiliated company

- Distributor

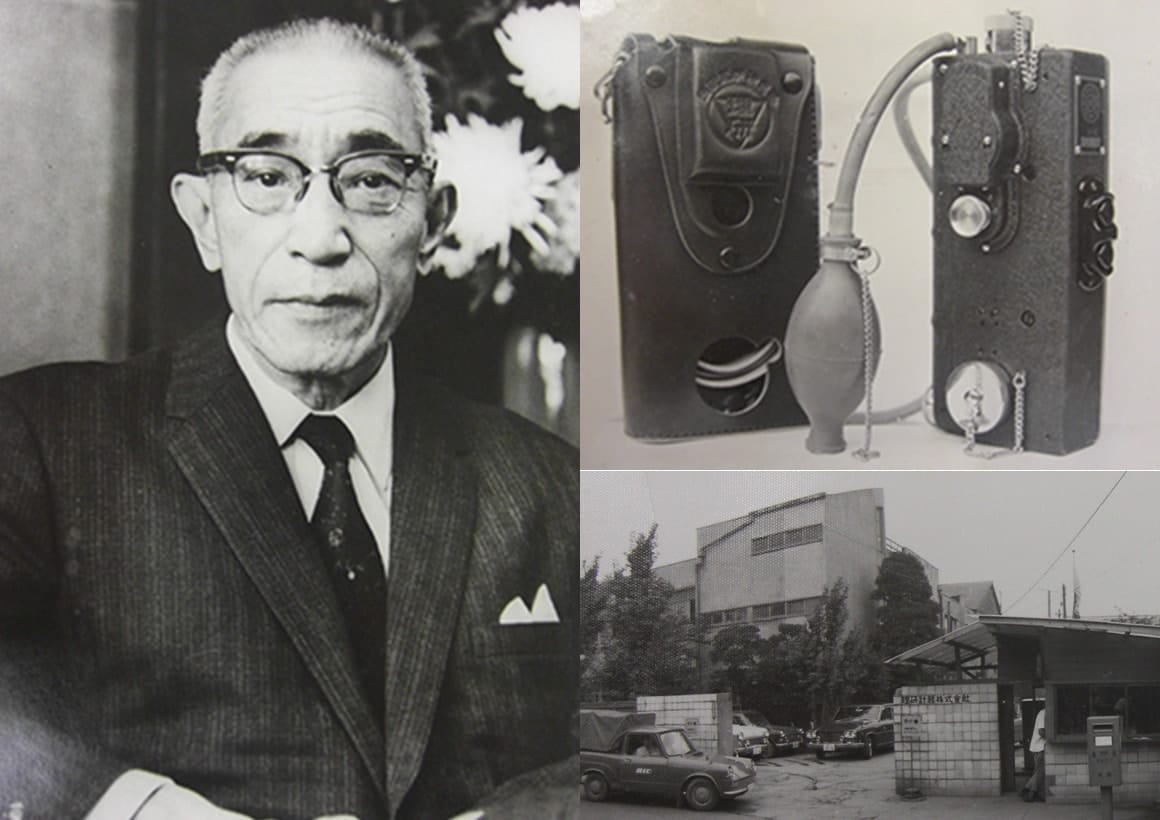

About us

Since our company was founded in 1939 under the umbrella conglomerate of RIKEN, our management philosophy has been to

create safe working environments. Our science and technology

research laboratories have developed industrial gas detection

warning devices, specializing in monitoring harmful gases in the

work environment, as well as for explosion prevention from

combustible gases. Without compromise, we continue to challenge ourselves to be technological leaders, developing and

manufacturing a wide range of industrial gas detection systems

and monitors. From large-scale gas detecting alarm systems to

small-sized personal gas monitors for safety protection; used in

many industries including semiconductor and LCD plants,

petroleum complexes, steelworks, various tankers, oil storage

stations, underground gas facilities, and volcanoes.

Experts in gas detection for over 80 years

The “RIKEN Gas Detector” utilizing the principle of light wave interference, was exhibited at the 1937 Paris World Exposition. Its subsequent use greatly contributed to the prevention of accidents in coal mines where many fatalities were prevalent at the time. On the 15th March 2019 we celebrated our 80th anniversary. Supported by our history and tradition we shall further improve long established technology, and continue to innovative. Developing reliable quality products in response to the diverse needs of industry.