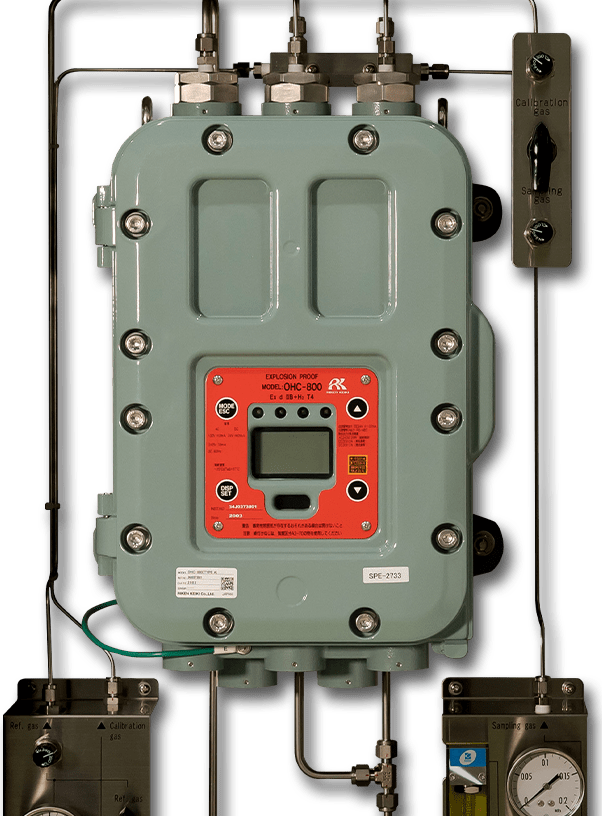

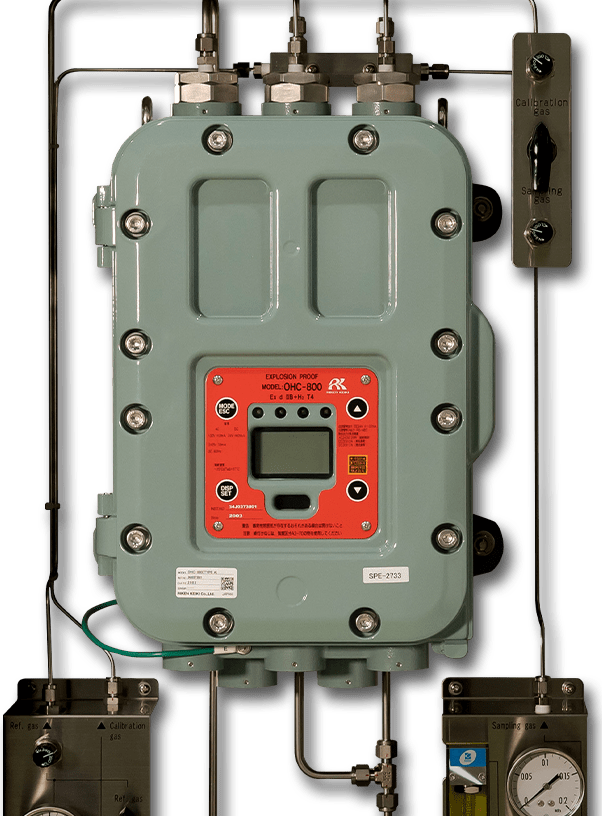

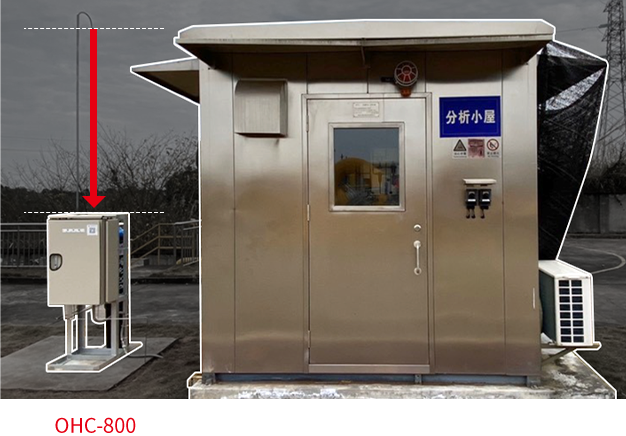

Explosion-proof gas calorimeter OHC-800

Support full range of fuel gases such as :

-

High accuracyOIML R140 class A

-Natural gas

-Natural gas + Hydrogen -

Continuous measurement

Data updated every 0.25 seconds

-

High-speed response

T90 within 5 seconds

About OHC-800

- Improve Combustion efficiency

- High-speed response / Stable calorific values

- Low maintenance costs

OHC-800

Address all Gas Calorimeter challenges!

| Detection method |

Opt-Sonic |

Gas

Gas chromatography(GC) |

Combustion type

Combustion type

|

Densimeter

Densimeter

|

|---|---|---|---|---|

| Accuracy |

Excellent

Repeatability: 0.02MJ/m3

|

Excellent

Repeatability: +/- 1.0%FS

|

Fair

Repeatability

High heating value: ±1.0% MJ/Nm3 Low heating value: ±1.5%MJ/Nm3 |

Poor

Effect by interference gases i.e.. CO2, N2

|

| Continuous measurement |

Excellent

Data updated every 0.25 seconds

|

Poor

Impossible

|

Excellent

Possible

|

Excellent

Possible

|

| High-speed response |

Excellent

T90 within 5 seconds

|

Poor

Analysis time 3-4 minutes

|

Fair

41-60 seconds or less

|

Excellent

T90 within 5 seconds

|

| Running cost |

Excellent

Measurement gas: 0.3L/min

Reference gas: 0.01 L/min(Air/N2) Sensor replacement: Not Necessary |

Poor

Measurement gas: 0.3-0.5L/min

Calibration gas: 1.2scf/day Sensor replacement: every 1 -3 years Carrier gas (He) : 50L/2years |

Fair

Measurement gas: 10L/min

Calibration gas: required Sensor OH: every 1 -3 years Instrument air: 50L/min |

Fair

Measurement gas: 0.1-1L/min

Calibration gas: required Sensor OH: every 2 -5 years |

Why Choose Riken Products

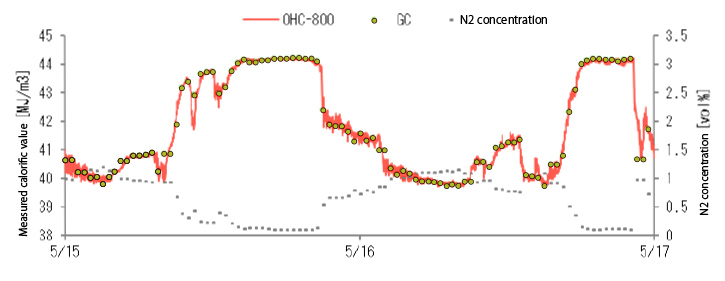

Continuous measurement

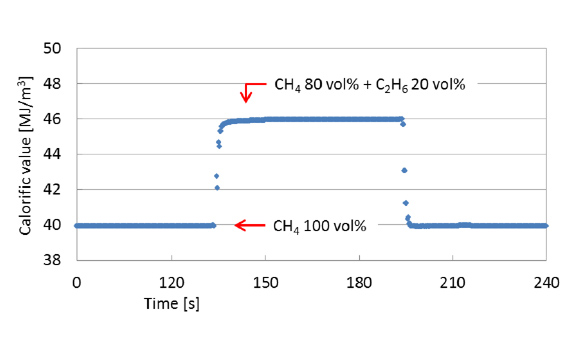

Measurement data can be updated every 0.25 seconds, a feature which is not possible with gas chromatography. Robust design for all measurement environments eliminates the risk of measurement outages.

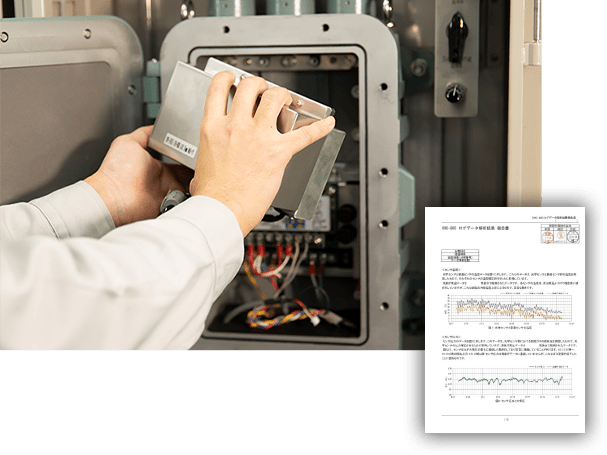

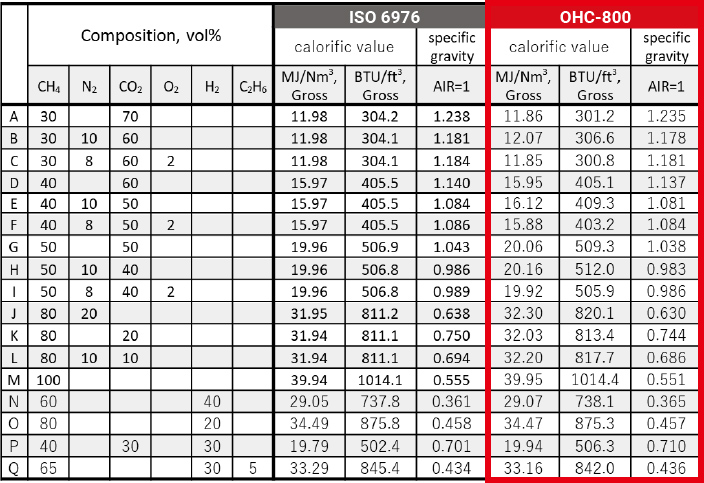

Comparison data of OHC-800 and GC measurements of fuel gas containing nitrogen. OHC-800 has the same high accuracy as the gas chromatograph, furthermore OHC-800 will perform continuous measurement, rapid change tracking without affected by N2, which is not able to be observed by GC.

High accuracy

By combining an optical sensor and a sound velocity sensor to perform unique calculations, the system is not affected by interference from gases that do not have heat content, such as N2, CO2, and O2.

The OHC-800 has OIML R140 the highest class “A” approval for natural gas, and a mixed gas of natural gas + hydrogen up to 20vol%.

<What is OIML?>

The OIML is an “international standard-setting body” in the sense of the World Trade Organization's Technical Barriers to Trade Agreement.

Click here and find the downloads for more details about OIML R140 and its certificate.

Click each item to see the details.

-

High trackability

High trackability

Measurement does not become erratic in the course of change but remains in a smooth curve.

-

Low running cost due to very low maintenance

Low running cost due to very low maintenance

Both types of sensors are non consumable, low maintenance, and contaminate resistant.

The reference gas consumption is 10 mL/min and the measurement gas is 300 mL/min. There is no need for carrier gas, as required for gas chromatography. It is also unnecessary to adjust sensitivity in the field.

-

Robust product structure

Robust product structure

a robust product design that can withstand harsh environments, eliminates the risk of sudden measurement outages.

Operating temperature: -20°C to +57°C

Equivalent to IP66/67

Various explosion-proof certified product ATEX/IECEX/FM/Japan EX

-

Multi layer durable design

Multi layer durable design

Log operating status and self diagnosis data, stored in the instrument for one year plus

Optional service available to analyze the log data and produce a graphical report for "operation status" and "diagnosis results" for the previous year.

In addition, a modular design means the sensor and the main unit can be easily replaced by the user.* Optional remote support for configuration changes and software updates. (Pending)

-

Various measurement gas types

Various measurement gas types

We can handle various gas types and compositions, such as natural gas, LNG vaporized gas, hydrogenated natural gas (H2 injection), LPG, LPG+AIR, oil refinery off-gas, biogas, steel by-product gas (COG, BFG, LDG) or their mixtures, and coal gasification gas.

-

Space saving

Space saving

The optimized design of the OHC-800 sampling components means installation can be undertaken in the smallest possible space.

-

Unit set-up can be customized to individual customer requirements

Unit set-up can be customized to individual customer requirements

We are able to customize a single unit to meet customer's requirements for measuring gases and applications. Please contact us for more information.

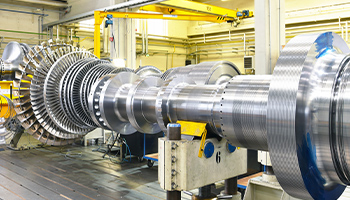

OHC-800 Applications

The OHC-800 has been introduced into various industrial sectors where calorimetric measurement is required, such as oil refining, steel industry, ship building, laboratories, universities, food industry, gas companies, turbine manufacturers, and glass manufacturers.

-

Optimization of air-fuel ratio for turbines and furnaces

Calorific efficiency brings stability and greater energy output which leads to increased turbine life and furnace efficiency. Therefore leading to lower maintenance and running costs and increased financial returns.

-

Calorific adjustment of natural gas or LNG vaporized gas

Cost Reduction of fuel gas and stabilization of quality

-

Calorimetry and composition analysis of steel by-product gas

Efficient reuse of steel by-product gas and improvement of the production efficiency by automating the operation of the furnaces properly

-

Calorimetric measurement of petroleum refined by-product gas

Efficient reuse of by-product gas

-

Power to Gas

(H2 injection and/or Methanation)Accurate calorimetry of natural gas containing hydrogen

-

Optimization of calorific values in glass production, pottery production and food production

Stabilization of product quality and improvement of production efficiency

-

Determination of transaction price

Real-time calorific value (CV) fiscal metering

* OIML R140 Class A Approval -

Methane Number (MN) measurement

Control and prevent engine knocking

-

Combustion optimization at waste incinerators

Maintain efficient or accurate combustion

Supported Gas List

- Natural gas

- Steel gases (COG,BFG,LDG)

- LPG

- Natural gas with Hydrogen

- Flare gas

- Methane

- Natural gas with LPG

- Boil-off gas

- E-methane

- Renewable natural gas

- Off-gas from refinery

- Butane

- Biogas

- Methanation gas

- Low calorie gases, and so on

- Biogas with LPG

- Hydrogen

Any other gases can be accommodated by customizing our sensors or the settings.

Feel free to contact us for more information.

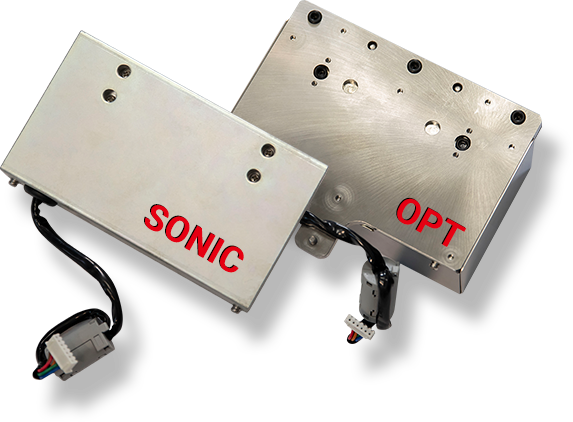

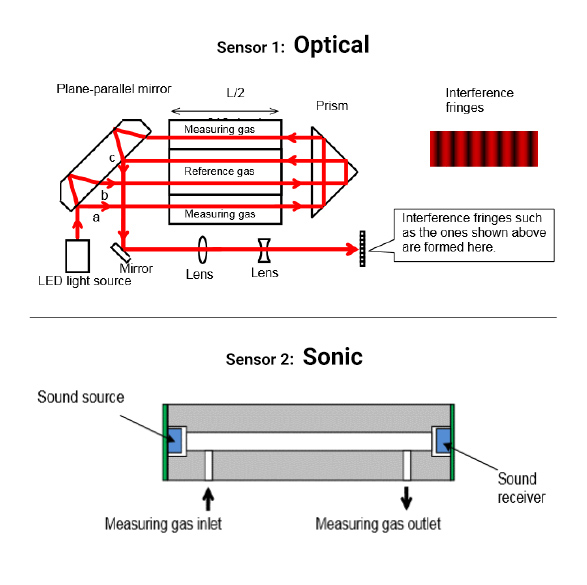

RIKEN OPT-SONIC method

World's first RIKEN OPT-SONIC method

Evaluating the calorific value of fuel gas by measuring the sound speed and the light speed passing through the fuel gas.

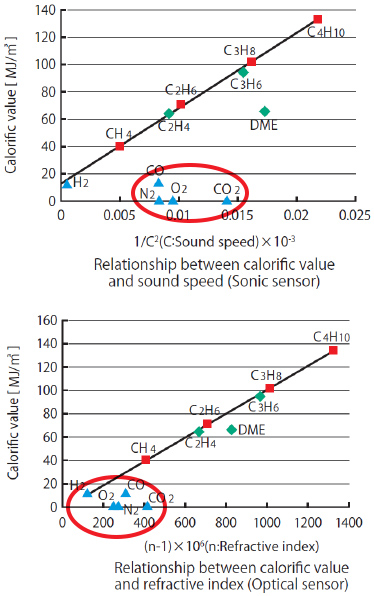

Measurement deviation caused by gas interference

The OHC-800 Opt-Sonic gas calorimeter uses two sensors, an optical sensor, and a sonic sensor.

Each of these sensors independently measures calorific value. When measuring fuel gases, interference gases such as N2, CO2, O2, and CO will affect the sensor response in different ways.

Riken Keiki discovered a correlation between these sensor response deviations caused by interference gases.

Applying the opt-sonic calculation means the effects of fuel gas interferences can be negated; ensuring truly accurate and repeatable Calorific Value measurements.

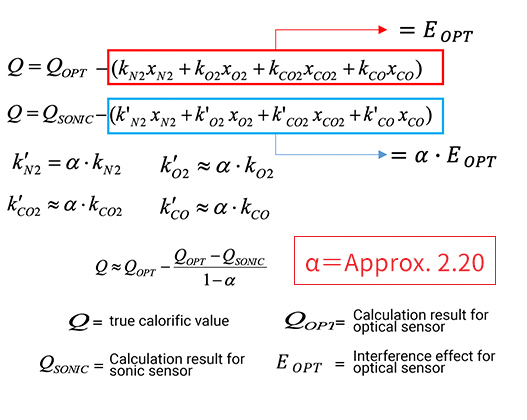

Opt-Sonic calculation explained

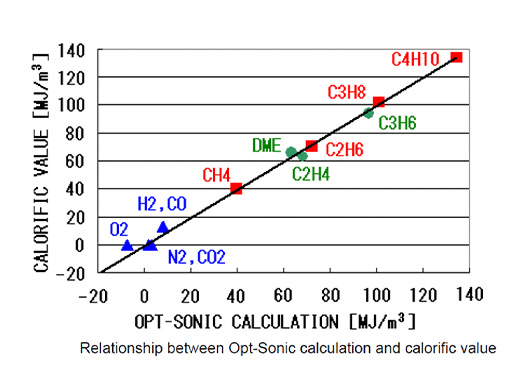

Riken Keiki have discovered a correlation between optical and sonic sensors whereby the ratio of measurement deviation remains constant, which is approximately 2.20 regardless of the gas type.

Applying the opt-sonic

calculation

Applying the opt-sonic calculation eliminates interference effects, thus giving truly accurate Calorific Value (CV) measurements.

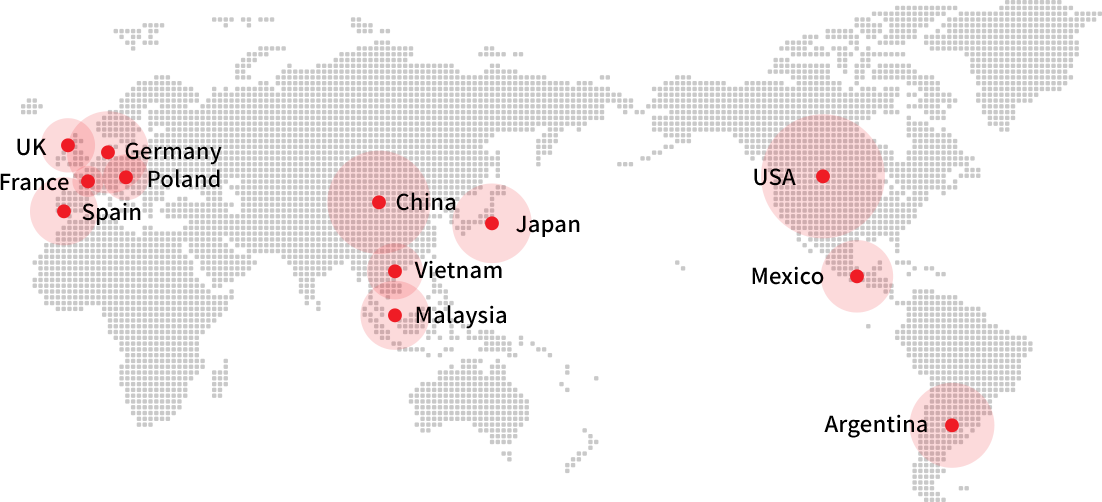

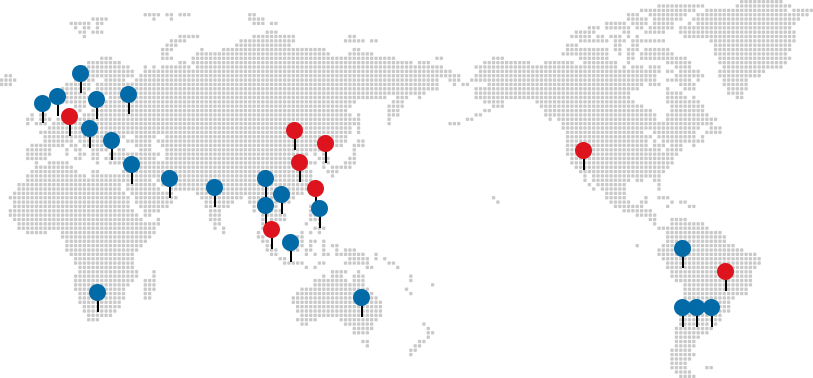

Proud of delivering over 200 units all over the world

We are proud to have delivered more than 200 units of OHC-800 to major engineering companies, gas companies, and turbine manufacturers all over the world.

Utilizing our established overseas network, we are expanding sales to overseas markets.

Customer Testimonials

Customer feedback from those already using the OHC-800.

Certifications / Approvals

-

ATEX Certified product

-

IECEx Certified product

-

FM Approved product

-

CE Marking

-

Japan EX Certified product

-

OIML R140 Class A

Certified product

Product Specification

- Model

- OHC-800

- Measuring principle

- Opt-Sonic method through measurement of light speed and sound speed

- Measuring gas (*1)

-

CH4 basis Paraffinic Hydrocarbon gases as represented by Natural Gas (*2)

- (*1) We are capable of measuring many types of gas. Contact us for details.

- (*2) Total concentration of interference gases such as N2, O2, CO2, CO etc. contained in a target gas is estimated as less than 20%

- Measuring targets

- Calorific value (Density / WOBBE index selectable)

- Measuring range (*3)

-

Calorific value : 25.00 - 50.00 MJ/m3 (Gross, 0 degree C, 101.325kPa converted)

Density : 0.500~1.500 MJ/m3 (Specific gravity converted)- (*3) Contact RIKEN KEIKI for the other measuring ranges

- Measuring method

- Constant-flow-rate gas introduction using external sampling devices

- Display

- Full-dot LCD (with backlight), 3 color LED lamp

- External Output

- 4-20 mA DC (isolated, source current type) maximum load resistance of 300 Ω / RS-485 communication

- Failure alarm

- Low flow, Sensor unit abnormality, Low light amount

- Failure alarm display

- Lamp (red) / Content indication on LCD

- Failure alarm contact (*4)

-

No-voltage contact 1a or 1b De-energize (Energize when alarming) or Energize (De-energize when alarming)

Contact capacity of 2 A, 30 VDC (resistance load)- (*4) Contact setting is adjustable

- Self-diagnostic function

- FUNCTION CHECK (warm-up or maintenance mode), MAINTENANCE REQUIRED, OUT OF SPECIFICATION

- Self-diagnostic display

-

FUNCTION CHECK, OUT OF SPECIFICATION : Lamp (orange) / Content indication on LCD

MAINTENANCE REQUIRED : Lamp (green) / Content indication on LCD

- Self-diagnostic contact

(*4) -

FUNCTION CHECK, OUT OF SPECIFICATION : No-voltage contact 1a or 1b

De-energize (Energize when alarming) or Energize (De-energize when alarming) Contact capacity of 2 A, 30 VDC (resistance load)

MAINTENANCE REQUIRED : SSR contact, contact capacity of 20 W, 240 VAC (resistance load)- (*4) Contact setting is adjustable

- Power supply

- 100 - 240 VAC ±10%, 50/60 Hz, max. 18 VA or 24 VDC ±10%, max.

5 W (The setting can be changed to either the AC or DC)

- Ingress Protection level

- Equivalent to IP66 and IP67

- Operation temperature

- -20 to+60 ℃ (-4 to +140 ℉)(ATEX / IECEx)/ -20 to+57 ℃ (-4 to +134.6 ℉)(Japan EX)

- Operation humidity

- 95%RH or less (no condensing)

- Outer dimensions / Weight

- Approx. 286 (W) x 453 (H) x 150 (D) mm / Approx. 23 kg (50.7 lbs)

- Explosion-proof structure

- Flame-proof enclosures (Explosion-proof class: ExdⅡB+H2 T4 <Japan EX>/Ⅱ2GExdⅡB+H2T4 <ATEX/IECEx>)

About us

Since our company was founded in 1939 under the umbrella conglomerate of RIKEN, our management philosophy has been to create safe working environments. Our science and technology research laboratories have developed industrial gas detection warning devices, specialising in monitoring harmful gases in the work environment, as well as for explosion prevention from combustible gases.

Without compromise, we continue to challenge ourselves to be technological leaders, developing and manufacturing a wide range of industrial gas detection systems and monitors. From large-scale gas detecting alarm systems to small-sized personal gas monitors for safety protection; used in many industries including semiconductor and LCD plants, petroleum complexes, steelworks, various tankers, oil storage stations, underground gas facilities, and volcanoes.

Experts in gas detection for over 80 years

The “RIKEN Gas Detector” utilising the principle of light wave interference, was exhibited at the 1937 Paris World Exposition. Its subsequent use greatly contributed to the prevention of accidents in coal mines where many fatalities were prevalent at the time.

On the 15th March 2019 we celebrated our 80th anniversary. Supported by our history and tradition we shall further improve long established technology, and continue to innovative. Developing reliable quality products in response to the diverse needs of industry.

International Network

We have established a mature global network of affiliated companies and distributors across all the world, so our products can be locally supported with confidence.