Are you still using gas

detectors at the end of

their service life?

Gas detectors are vital equipment that can

have life or death consequences. Use them

properly to protect crew members from accidents.

SCROLL

Maintenance of vessels in dry dock is mandatory twice every five years*

*Dry dock cycles are specified in SOLAS 74/88 Regulation I/10(a)(v) (Ref: Maritime_Circular_No13_ -Dry_Dock_Extension_Policy).

Do you ensure that the gas detectors onboard the ship are inspected on an routine basis?

Gas detectors and other precision equipment generally have a service life of 10 years in a clean environment. It is recommended that gas detectors be inspected, repaired and replaced by manufacturers during the ship inspection twice every five years.**

**Compulsory classification/inspection of ships in drydock (for NK) as stipulated in the Steel Shipping Regulations "020_part_b_j_2022".

Continued use of old gas detectors without maintenance is dangerous. They may fail to detect gas properly due to stain, dust or physical damage.

To ensure

the safety

Pay attention to support termination information. It is recommended that any gas detector at the end of its service life be replaced with the latest model for the purpose of ensuring maintenance, inspection and the reliable supply of spare parts.

Stationary gas detectors

Compact and lightweight smart type gas detector. Robust enclosure construction, combined with a variety of options,

makes them suitable for outdoor installations and harsh environments. Contributes to the construction of a

comprehensive disaster prevention system by connecting to an indicating alarm unit and central monitoring room.

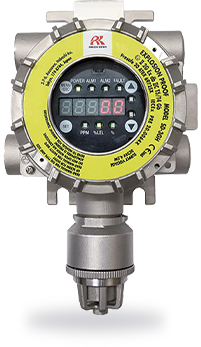

Detector Type ー 01

Cost-effective products

supported by a

comprehensive system

Compact and lightweight smart type gas detector. Robust enclosure

construction, combined with a variety of options, makes them suitable

for outdoor installations and harsh environments. Contributes to the

construction of a comprehensive disaster prevention system by

connecting to an indicating alarm unit and central monitoring room.

-

SD-1RI

- Diffusion type

- Non-Dispersive Infrared Method

- Self diagnosis by microprocesso

-

SD-1RI-T

- Direct insertion type

- Non-Dispersive Infrared Method

- Self diagnosis by microprocesso

-

SD-1OX

- Diffusion type

- Membrane Type Galvanic Cell Method

- Self diagnosis by microprocesso

-

SD-1EC

- Diffusion type

- Potentiostatic Electrolysis Method

- Self diagnosis by microprocesso

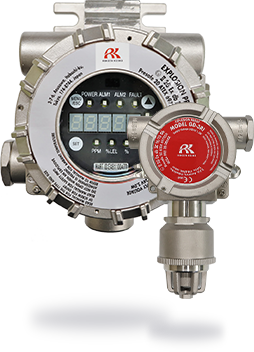

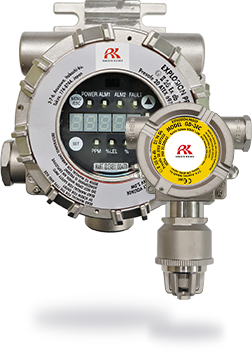

Detector Type ー 02

High-performance and high-functional products compatible with many different plants

A series of high-performance models certified with multiple international standards so that they can be used in various plants A lineup of models with five detection principles that differ in detectable gases and concentrations ensures the detection of a wide range of gases Featuring a sensor equipped with a microcomputer and a sturdy stainless steel case, it operates under a broad range of conditions, from extremely cold to tropical situations.

Detector Type ー 02

-

SD-3RI

- Diffusion type

- Non-Dispersive Infrared Method

- Next generation high performance sensor

-

SD-3EC

- Diffusion type

- Potentiostatic Electrolysis Method

- Next generation high performance sensor

-

SD-3SC + GD-3RI

- Remote type

- Non-Dispersive Infrared Method

- Next generation high performance sensor

-

SD-3SC + GD-3EC

- Remote type

- Potentiostatic Electrolysis Method

- Next generation high performance sensor

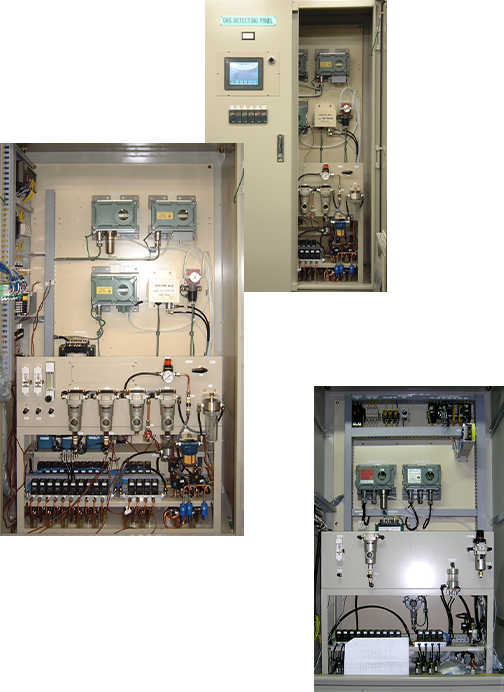

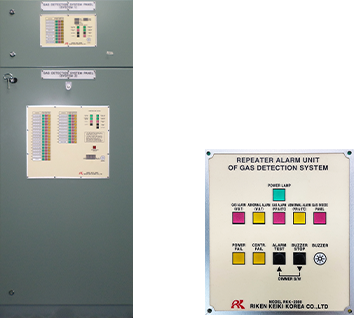

Gas Sampling System

Our gas sampling systems are equipped with original sensors designed to measure different types of gases and are certified with multiple standards. (ATEX/MED/ABS/DNV/KR/RINA)

Specially designed for the ship market, they have all the functions needed for on-board gas detection.

In the event of replacing a fixed gas detector, it is possible to replace an aged internally installed gas detector while retaining the existing panel, according to your budget or convenience.

-

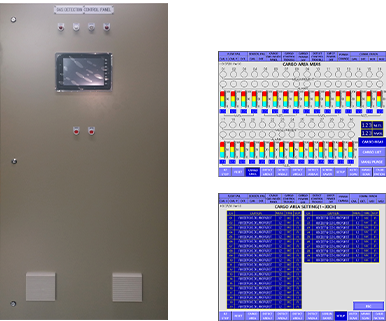

Fixed Gas Detection System For Special Ship

・Touch Panel Switch LCD Screen Display

・Flexible System Configuration(Remote LCD)

・Communication With IAS by Modbus

・Provide Trip Contact

・Saves Installation Space

・Auto Purge Function for Removing Suction Condensate -

Fixed Gas Detection System For General Ship

・Simple and Compact Design

・Integrated Sampling and Monitoring for W.B.T, P/R and Accommodation Area

・Combined Design

・Auto Purge Function for Removing Suction Condensate

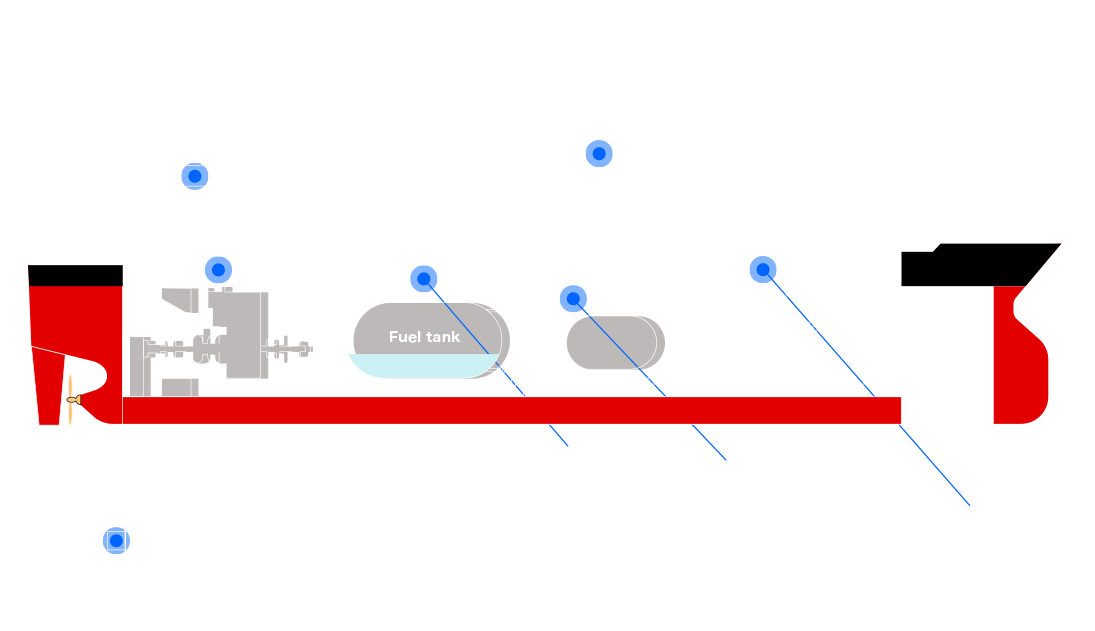

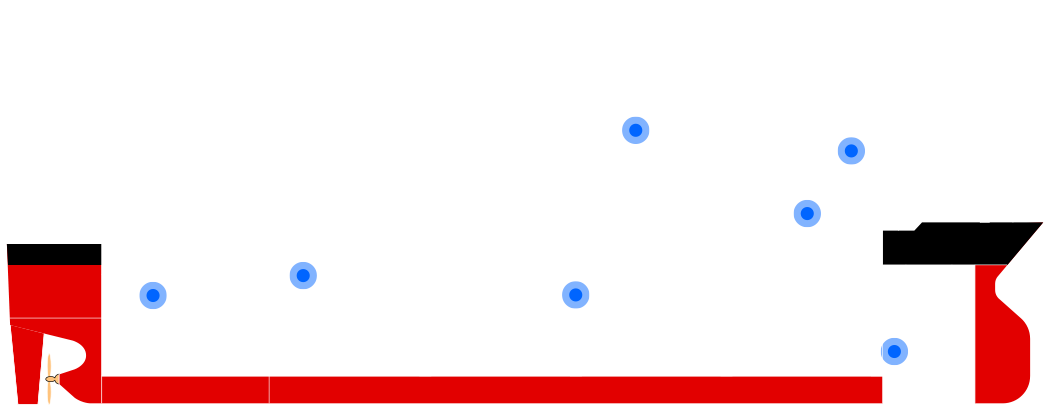

Application examples (Detection points)

For both conventional and next-generation fuel carriers, installation of an appropriate number of gas detectors and frequent inspection and maintenance will ensure proper gas detection.

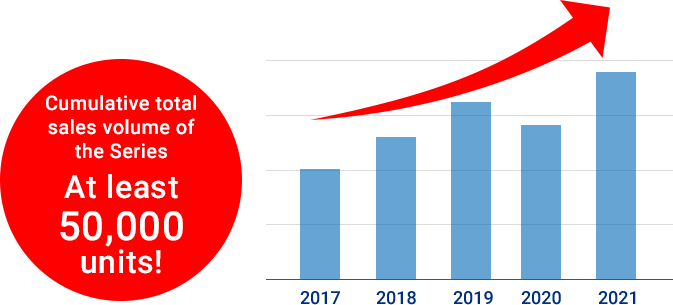

Our sales reference

for marine industry

-

RIKEN KEIKI gas detectors are selected by the shipping industry around the world. At least 50,000 units have been sold.

-

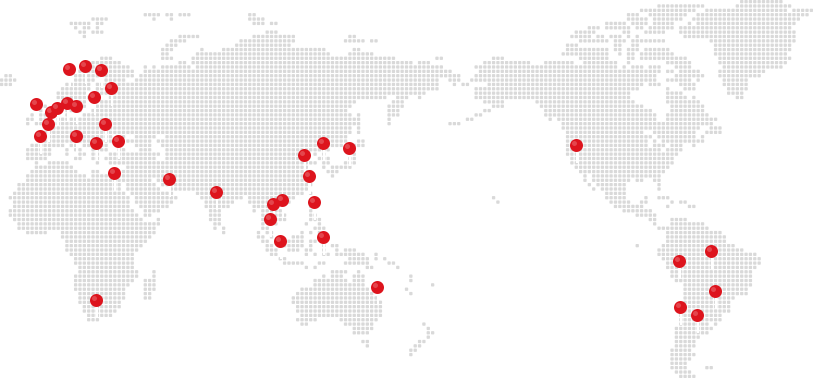

International Network

Repair and replacement

services available at

major ports worldwide

RIKEN KEIKI boasts a service network that stretches to major ports worldwide, including those in North and South Americas, Europe, Russia, the Middle East, Asia, Oceania and Africa. We offer a broad array of services, including product repairs at dry dock and parts supply and sales.

To the Future

Customer Inquiry Process

FREE

-

① Inquiry and

consultationFirst, please send us your inquiry using the contact form.

At the time of inquiry, please specify the Inst. No., IMO No. and similar information. For details about completion, please refer to the Inquiry Form. -

② Assessment

We will try to understand the challenges you are currently facing or requirements you may have. Please feel free to ask about cost, lead time, or other issues you may be unsure about.

-

③ Proposal and

estimateBased on your requirements, we will propose a suitable solution/system and cost estimate through your local Riken Distribution partner

![]()

④ PO and Delivery

If you are satisfied with the proposal and estimate, please place your order to your local Riken distributor and we will fulfill it accordingly.

Customer Feedback

Many customers use RIKEN KEIKI gas detectors due to their safety, and our high-level product development capabilities.

For other applications, please contact us.

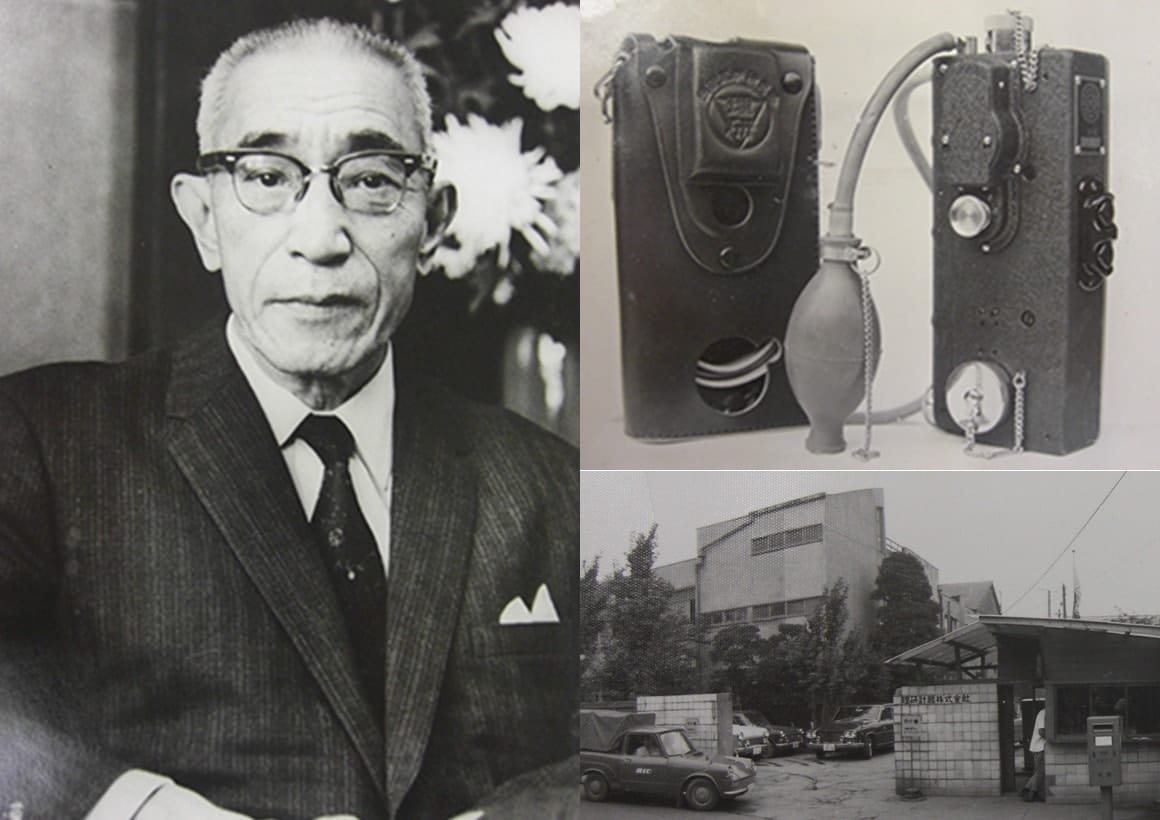

About Us

Since our company was founded in 1939 under the umbrella conglomerate of RIKEN, our management philosophy has been to create safe working environments. Our science and technology research laboratories have developed industrial gas detection warning devices, specializing in monitoring harmful gases in the work environment, as well as for explosion prevention from combustible gases. Without compromise, we continue to challenge ourselves to be technological leaders, developing and manufacturing a wide range of industrial gas detection systems and monitors. From large-scale gas detecting alarm systems to small-sized personal gas monitors for safety protection; used in many industries including semiconductor and LCD plants, petroleum complexes, steelworks, various tankers, oil storage stations, underground gas facilities, and volcanoes.

Experts in gas detection for over 80 years

The “RIKEN Gas Detector” utilizing the principle of light wave interference, was exhibited at the 1937 Paris World Exposition. Its subsequent use greatly contributed to the prevention of accidents in coal mines where many fatalities were prevalent at the time. On the 15th March 2019 we celebrated our 80th anniversary. Supported by our history and tradition we shall further improve long established technology, and continue to innovative. Developing reliable quality products in response to the diverse needs of industry.