Requesting inspections and repairs

(Process from initial estimate to order and work implementation)

(Process from initial estimate to order and work implementation)

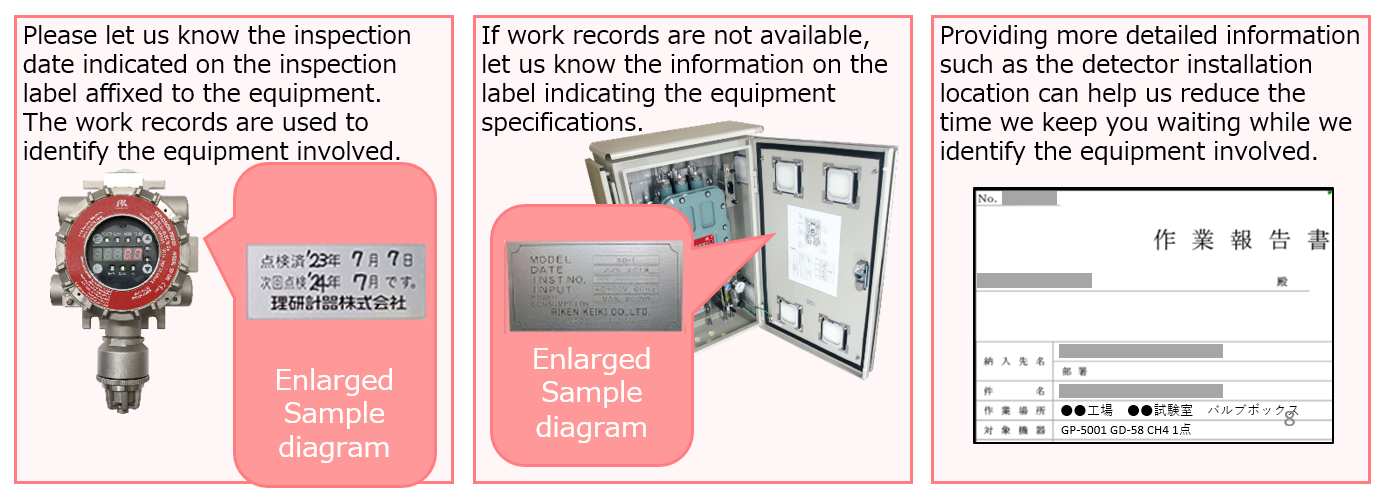

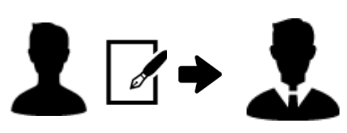

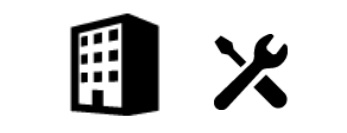

Checking the equipment number or previous work record information will enable work to be carried out more efficiently. Information on the previous inspection can be found on the labels attached to the equipment as shown in the figure below.

Contact RIKEN KEIKI.

2. Place order to RIKEN KEIKI

Confirm the order once you agree with the cost and details outlined.

(* Work implementation confirmed)

3. Work carried out

Once we receive the product, we will carry out the necessary work at our factory.

* The exact details will differ for fixed, portable, and analysis equipment.

4. Additional parts replacement

If additional work or parts become necessary on-site, we will request additional fees and additional orders.

5. Test results report

We will issue a test report outlining the work carried out.

This will include details of areas requiring separate repairs and recommendations regarding replacement due to the age of the equipment.

Fixed products

Inspections and repairs of fixed gas monitoring systems will be handled by RIKEN KEIKI service engineers who will visit the site where the equipment is installed.

Although we have the largest number of bases and personnel in Japan, it may often be necessary to adjust scheduling to provide on-site support. Bringing inspection and maintenance equipment and calibration gas on to the site may cause some inconvenience, but we appreciate your cooperation.

Portable products

Portable gas detection monitoring systems will be inspected and repaired at one of our nationwide service sites or the service headquarters.

In the case of repairs following faults, we may need to hold on to the equipment temporarily for assessment, which could extend the time required from the request until the equipment is repaired and returned. Please feel free to consult with us if scheduling it tight concerning the equipment usage plans.

Analysis equipment

RIKEN KEIKI analyzers are products designed for precision measurement. Inspections and repairs are therefore handled by engineers with specialist knowledge. The action required is frequently dependent on the individual product usage and configuration, so we will make preliminary consultations to confirm the situation before proceeding with the work.

Click here for list of offices

1. Initial estimate

We will check the work details in advance to provide an estimate.

* Example: The alarm continues to sound even when no gas is present.

→ Estimate for replacing gas sensor