RIKEN KEIKI products

RIKEN KEIKI is committed to creating products with enhanced self-diagnostic functions to minimize daily inspection items and ensure a more reliable environment to enable users to use our products with confidence.

Daily maintenance case studies

Portable gas detectors

Battery level and concentration display check

① Battery level check

・ Check that the battery level is sufficient.

② Concentration display check

・ Measure fresh air and check to confirm that the reading is zero (20.9 % with oxygen meter).

・ If the reading is offset, confirm that there is no interference gas in the vicinity, then perform zero adjustment (fresh air adjustment).

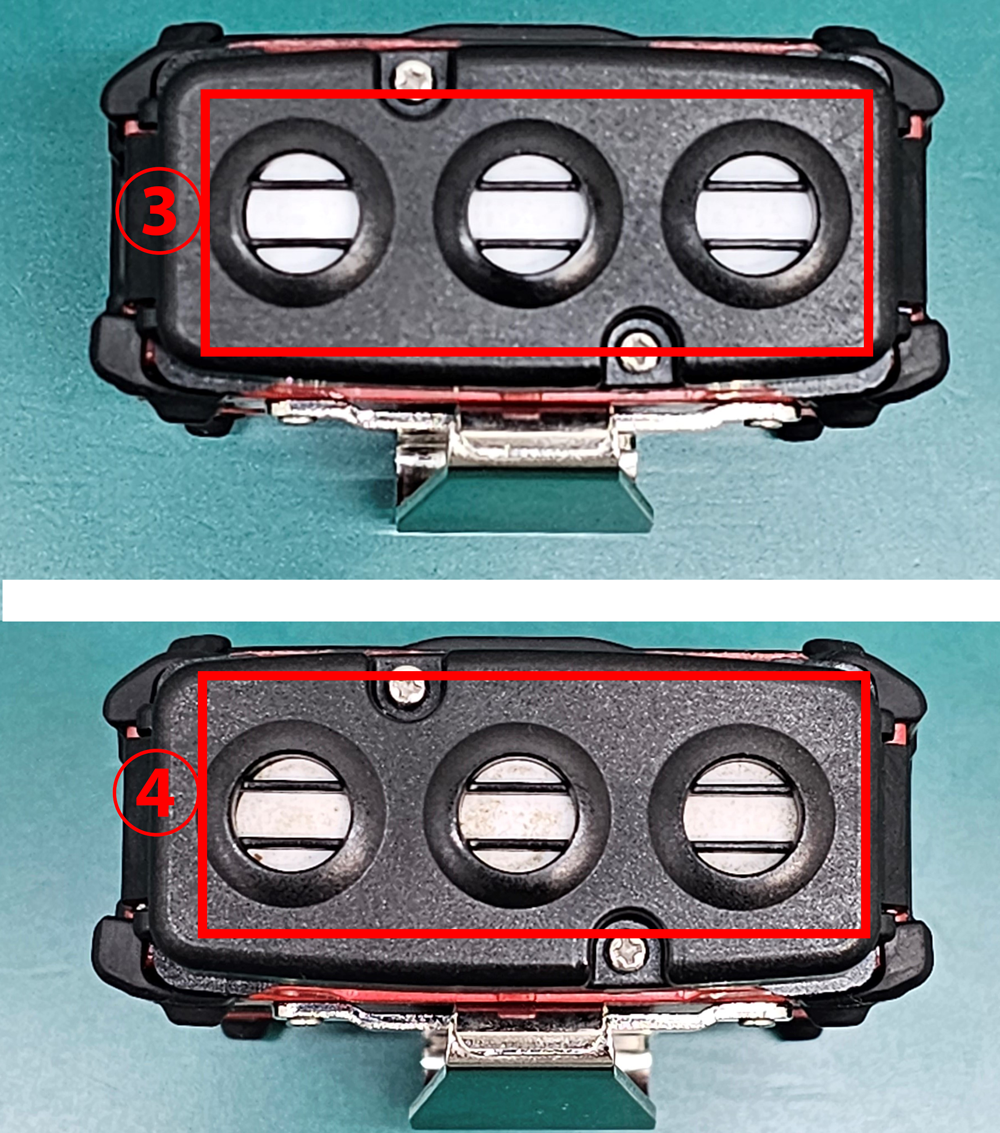

Filter check

・ Check to confirm that the filters are not dirty.

③ If OK: They can be used if not dirty.

④ If not OK: Contact RIKEN KEIKI if dirty.

Fixed gas detectors

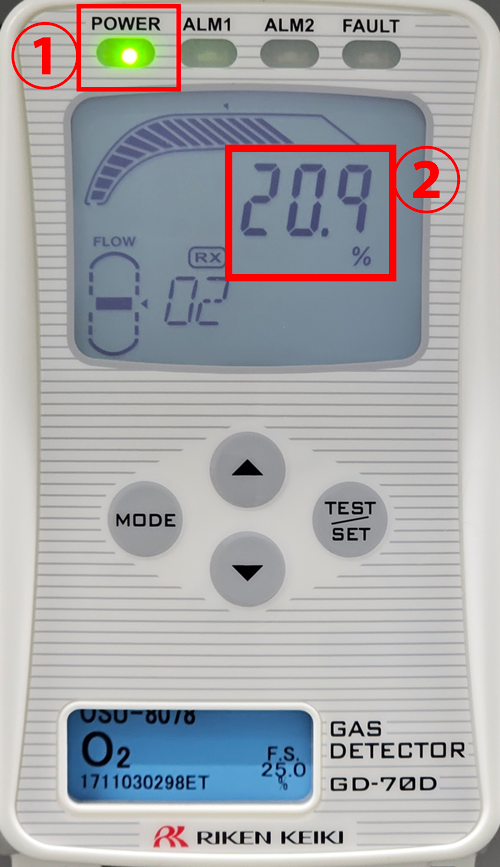

Power supply and concentration display check

① Power supply check

・ Check that the power supply lamp is lit.

② Concentration display check

・ Measure fresh air and check to confirm that the reading is zero (20.9 % with oxygen meter).

・ If the reading is offset, confirm that there is no interference gas in the vicinity, then perform zero adjustment (fresh air adjustment).

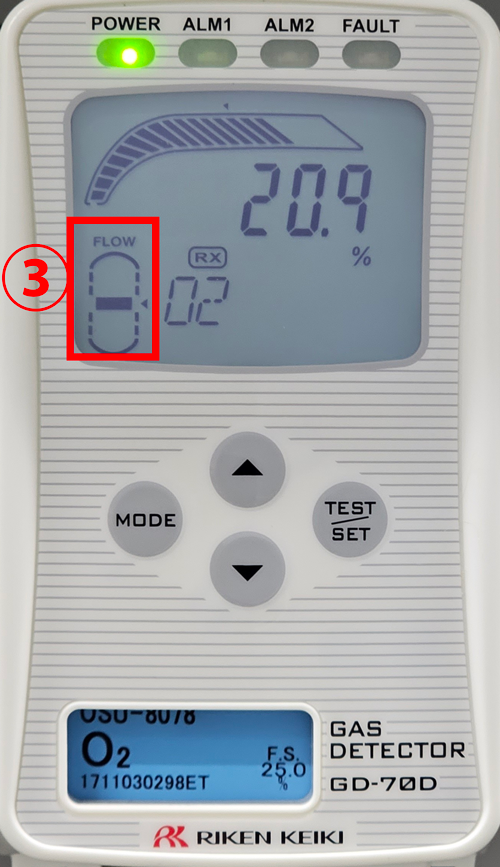

Flow rate check (OK)

③ Check the flow rate indication to confirm the absence of abnormalities.

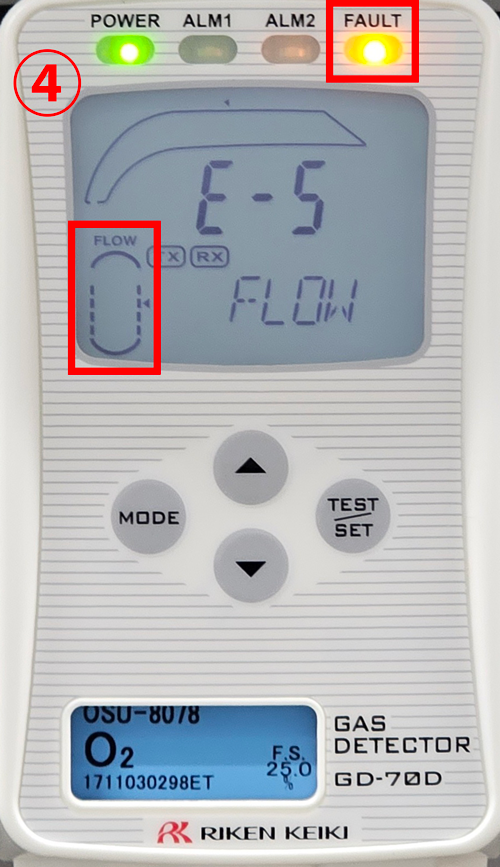

Flow rate check (flow rate error)

④ The filter or pump needs to be replaced.

Replace with new items, or contact RIKEN KEIKI.

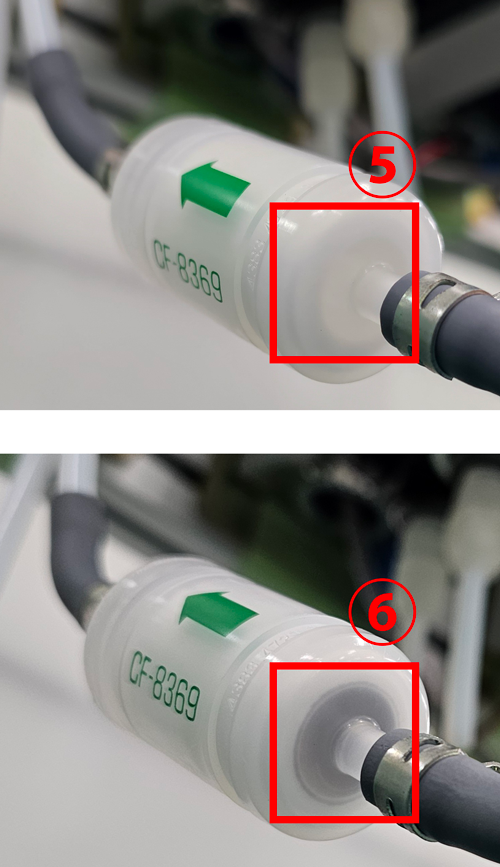

Filter check

・ Check to confirm that the filters are not dirty.

⑤ OK: They can be used if not dirty.

⑥ If not OK: If dirty, replace with new items, or contact RIKEN KEIKI.