Customer Feedback

At Riken Keiki, we share the feedback from our customers as valuable information and reflect it in the development and improvement of our products and services. We regard this as a precious asset.

At Riken Keiki, we share the feedback from our customers as valuable information and reflect it in the development and improvement of our products and services. We regard this as a precious asset.

Portable gas detectors continue to prove their worth in a wide range of working environments where hazardous gases are present, including work underground, inside manholes, and in steel plants and on tankers. Riken Keiki products are valued by customers worldwide for their detection performance, ruggedness, and compact, lightweight design that stays out of the way for work on-site. During maintenance or whenever opportunities arise, we strive to deepen communications with our customers and to elicit their views on our products, including their comparisons with products from other manufacturers, and regard all this as valuable information for future product development and improvement. Here we’ll describe some of the positive feedback we’ve received from our customers, both in Japan and overseas.

CASE 01: Long-term popularity attests to capabilities

From a safety manager customer in the US

US OSHA regulations mandate wearing in the breathing zone.

Compared to detectors from other manufacturers, the GX-3R and GX-3R Pro are ideal, as they’re small and lightweight. We’ve been using the long-selling GX-2001 and GX-2009. We’re great fans of the brand.

CASE 02: The combination of ease of use and detection performance ensures safe working environments!

From a manhole cleaning company in the US

For work in confined spaces—for example, when cleaning inside concrete drums—the compact size and ability to detect low CO2 levels make this detector highly appealing. The combination of compact size and CO2 detection capability is what prompted us choose this model. In addition to not interfering with work duties, gas detectors capable of detecting low CO2 levels down to TLV 5,000 ppm = 0.5 %vol help us ensure work safety.

CASE 03: Light in weight and ease of wearability are big positives!

From a manhole interior worker in Japan

It’s no good if trying to detect gas ties up our hands so that we can’t handle other tasks. The GX-3R and GX-3R Pro can be worn directly on the body, reducing our workload.*1 In addition to belt clip mounting, these detectors can be worn attached to a helmet or ankle for flexibility in how they’re used in specific work environments.*2 *1: The GX-3R weighs approximately 150 g. *2: Using optional accessories

CASE 04: From the viewpoint of a site manager, we made the right decision in selecting this product!

From a steel plant customer in Japan

We issue the GX-3R Pro to our work crews to ensure safety. Our expansive working area makes it hard for me, as a manager, to oversee conditions, and this product lets us receive direct notifications and keeps us informed of the situation, which gives site managers peace of mind. The products are also popular with our workers, as they’re lightweight and easy to use, and knowing their surroundings are constantly being monitored provides reassurance.

CASE 05: Assures workplace safety even inside ships on international routes!

From a ship interior worker in Japan

We use them on vessels. Knowing that they comply with the SOLAS Convention and MED and that they’re approved by the coast guards of various countries is reassuring. The availability of an extensive lineup of tools, including bump test devices, is an advantage and makes it easy to check performance onboard vessels.

Riken Keiki fixed gas detectors are used in plants across a broad range of industries. Our primary goal is to provide solutions to our customers. We offer a wide range of products to suit the characteristics of specific industries and facilities, installation locations, and cost requirements, including products based on our proprietary optical interferometric method. Our field engineers seek out customer feedback when visiting their sites for regular maintenance or other matters, and we apply this information internally to strengthen product development and to guide improvements. Here we present some of the customer feedback as a way to help you select the ideal gas detector for your needs.

From a printing company customer who uses the FI-800

If only we’d consulted with Riken Keiki from the start...

We initially tried cutting costs by using gas detectors just as measuring instruments, but we had to replace the sensors repeatedly because they couldn’t withstand the conditions of the operating environment, and in the end that led to huge budget overruns. After that, we switched to the FI-800 and were really satisfied by the reassurance it provides. The performance and eliminating unexpected operating costs helps us get our work done. Now we know we should have chosen the optical interferometric method from the start.

From a food company customer who uses the FI-900

It’s also an incredibly effective analyzer!

At first, we used it solely as a gas monitor, but found it’s also great for measuring purity as the results are highly repeatable, and we also use it as an effective inline monitoring system. In fact, we also use it a lot as an analyzer. Eliminating the constant need to replace parts also cuts operating costs, something the manager is really happy about, and I’m proud of my decision.

Riken Keiki analyzers are widely used by researchers in diverse fields ranging from research and development to cultural heritage protection. We inspire researchers, contribute to new discoveries, and help generate results that were never anticipated. We maintain contact with our customers in various ways even after product delivery, and continue to consult with them and respond to complex requests, a process that generates significant comments and feedback. We apply this valuable input to future product development. Here, we present some interviews with researchers who actually use our products.

Special interview 1: Used extensively in efforts to preserve cultural heritage: Professor Kirino from the Tokyo University of the Arts explains the appeal of the DF-01

Retired Tokyo University of the Arts

Graduate School Art Research Department Cultural Property Preservation Division

Conservation Research Area Art Material Research Lab

Professor Fumiyoshi Kirino

-- Profile

Born 1956 in Tokyo.

Received Ph.D. from Tohoku University Graduate School Engineering Research Department in 1981, following completion of master’s degree at the Tokyo Institute of Technology’s Interdisciplinary Graduate School of Science and Engineering. Worked for approximately 18 years at the Hitachi Central Research Laboratory Involved in research on topics like battery materials and optical/magnetic recording Appointed Assistant Professor at the Tokyo University of the Arts Graduate School in December 2000; appointed Professor in 2010 He specializes in materials science and conservation science. He belongs to approximately ten different academic societies, including the Japan Society for Scientific Studies on Cultural Properties (JSSSCP). Recipient of numerous awards, including from the Japan Institute of Metals and Materials (JIM) and the Institution of Professional Engineers, Japan (lPEJ).

Since 2016, he’s been involved with the Japan International Cooperation Agency (JICA) Grand Egyptian Museum construction project, providing technical support for the conservation, restoration, and display of the treasures of King Tutankhamun. The museum is scheduled to open in 2021. Teamwork is essential in work involving conserving and restoring cultural assets. Professor Kirino’s warmth and friendliness helped establish a united team.

He retired from Tokyo University of the Arts in May 2023.

Portable Composite X-ray Analyzer

DF-01

Japan possesses world-renowned technologies for cultural property conservation and restoration.

Professor Kirino has been involved in work to conserve and restore Egyptian treasures for roughly the past ten years.

His full-scale involvement began following agreements for multi-faceted cooperation across a wide range of projects in which the Japan International Cooperation Agency (JICA)

provided yen loans to the Egyptian government as ODA for the Grand Egyptian Museum (GEM),

scheduled to open in 2021, together with technical support and personnel training in areas related to the analysis and restoration of important ancient Egyptian properties.

At the request of JICA, Professor Kirino has been involved in the restoration of 72 different artifacts ranging from wooden items to fabrics and murals over the three-year

period since November 2016.

When he arrived on the scene, he recalls, there was initially some friction with the local specialist staff, who, confident in their skills at conserving and restoring the world’

s oldest artifacts, wouldn’t let anyone other than Egyptians touch the relics. But the barriers gradually faded, replaced by a relationship of mutual trust and respect

once the unique current condition analysis methods and restoration techniques offered by Japan as well as sincere attitudes of Japanese staff became apparent.

“Understanding the current condition is the most important aspect of work to conserve and restore cultural properties. We can then apply this to obtain the

information needed for conservation and restoration and to consider ways both to return artifacts to a condition as close as possible to their original condition and to prevent future deterioration.”

Outside Japan, small parts of artifacts are removed for analysis, but in Japan, non-destructive methods that avoid damaging artifacts—for example, using X-rays or ultraviolet light—

are used to analyze and identify details such as age, location, paint constituents, and metal composition.

“They were amazed by these methods. Another restoration technique unique to

Japan makes use of thin, high strength washi paper, which we applied to keep the surface of murals intact during restoration. I think it’s a major accomplishment that the Egyptian government

recognized Japanese conservation and restoration technologies in this project.”

The enthusiastic efforts by Professor Kirino and his team were rewarded by a decision to include descriptions in Japanese on exhibition plates at the GEM.

First encounter with the DF-01 and its appeal

Professor Kirino recalls his first encounter.

“I was watching a program on TV about scientific measurements of the gold mask of King Tutankhamun, which made me want to get hold of the same type of measuring instrument for my university, and then,

through an acquaintance, Riken Keiki contacted me to say that they would provide a measurement demonstration. When the day arrived, I was really excited to see they

’d brought the same instrument I’d seen on TV with them. I then really wanted to get hold of one, and although we didn’

t have the budget needed at the time, I didn’t give up, and a few years later we finally purchased one.”

When asked about the appeal of the DF-10, as an actual user, Professor Kirino responds, “

First, there’s its mobility. The vast majority of Japanese cultural properties are in desperate need of conservation and restoration, but can

’t easily be moved due to their fragility. The only way to preserve these treasures for future generations is for us to go to

wherever they happen to be. If I receive a request, I’

ll travel anywhere in the country with my DF-01.

Of course, being able to use both X-ray fluorescence and X-ray diffraction analysis is also a major breakthrough. The advantages of this is that we can use

X-ray fluorescence to identify elements and X-ray diffraction to identify substances. Being able to perform analyses without having to rely on experience and assumptions

has a major impact on subsequent conservation and restoration work. Another point adding to its appeal is the flexibility of being able to make non-contact measurements, regardless

of size or shape, such as for thin items like silk cloth, small decorative metal parts, painting scrolls, and statues of Buddha. Thanks to this instrument, we’

ve been able to measure a wide variety of cultural artifacts, including scrolls belonging to the Imperial Household Agency and a helmet belonging to the feudal lord Kuroda

Nagamasa and currently owned by the Fukuoka City Museum.”

“I love playing with measuring instruments,“ Professor Kirino adds. “And the DF-01 has all kinds of built-in features. The instrument is also appealing in the various ways it can be used, based on new ideas from users, which constantly surprises the developers. That’s also made me a bit of nuisance to the people at Riken Keiki, as I continually ask them all kinds of questions and prod them to follow up on various ideas. The development and design staff always take my requests seriously, which proves there’s a level of camaraderie and mutual understanding there, and that we’re all perfectionists at heart. I think this is one of the attractions of how Riken Keiki works.”

Science serves as the starting point when wishing to conserve or restore cultural assets

“The starting point for the conservation and restoration of cultural properties is to analyze and evaluate the current state, and the power of science makes this process even more accurate.

One of my duties is to map out this route. It’s also important for me to help develop both Japanese and overseas students to become worldwide human resources.

The DF-01 has drawn interest from both cultural property conservation and restoration societies and overseas students, and I have high hopes for future progress at Riken Keiki.

My university is home to a full range of specialists active in areas ranging from scientific measurement and analysis to conservation and restoration work,

and my dream is to play a role as central liaison in future cultural property conservation and restoration efforts. In this too, I want Riken Keiki to be at my side as an ideal partner.

As a scientist, I’m both amazed and thrilled every time we discover a new skill, like the nanotechnologies created by my predecessors. On certain days, we struggle, as we can’t always accurately analyze or explain things, but I’ll never give up in my efforts to convey my excitement to as many people as possible and to future generations.” With a youthful glint in his eyes, Professor Kirino looks firmly both into the past and the future.

The picture scroll is measured by

DF-01

The helmet of samurai warrior

Special Interview 2: Striving to make Perovskite solar cells a practical reality to achieve a carbon-free society

The University of Tokyo Research Center for Advanced Science and Technology

Energy and Environment Segawa Laboratory

Project Professor Satoshi Uchida

-- Profile

Born 1965 in Sendai, Miyagi Prefecture Grew up in Hirosaki, Aomori Prefecture

Began his career as a researcher at Tohoku University in 1991 after majoring with a master’s degree in applied chemistry at the Tohoku University Graduate School of Engineering.

Received Ph.D. in 1996 (with a Tohoku University research paper titled “Leaching Ni, Cu, Zn, and Sn from metal scrap using high-temperature aqueous solutions”); has worked from 2006 as a specially-appointed assistant professor at the The University of Tokyo Research Center for Advanced Science and Technology.

Research and employment history

April 1991 Tohoku University Research Institute of Mineral Dressing and Metallurgy Research Center for Difficult Treatment of Rare Resources

・Employed as Research Associate

・Research on metal leaching from ores using high-temperature aqueous solutions

April 1994 Reassigned as assistant at the Tohoku University Institute for Advanced Materials Processing

・Research on hydrothermal synthesis of industrial inorganic materials

April 1996 Reassigned as assistant at the Tohoku University Institute for Chemical Reaction Science

・Research on photocatalysts and ceramic powder synthesis using hydrothermal reactions

April 2001 Reassigned as assistant at the Tohoku University Institute of Multidisciplinary Research for Advanced Materials

・Research on hydrothermal synthesis of nano titanium oxide powder and dye-sensitized solar cells

November 2006 The University of Tokyo Research Center for Advanced Science and Technology

・Appointed special assistant professor

・Research on dye-sensitized solar cells and titanium oxide sponge

April 2007 The University of Tokyo Research Center for Advanced Science and Technology

・Associate Professor

・Dye-sensitized solar cells

May 2012 The University of Tokyo Komaba Organization for Educational Excellence Special Energy and Environment Department

・Project Professor

・Dye-sensitized solar cells and Perovskite solar cells

May 2017 The University of Tokyo Research Center for Advanced Science and Technology

・Project Professor (up to present day)

・Perovskite solar cells

Academic society membership

The Chemical Society of Japan, The Iron and Steel Institute of Japan, The Japan Institute of Metals and Materials, The Ceramic Society of Japan,

The Electrochemical Society of Japan, Society of Computer Chemistry, Japan, The society of Iodine Science, MRS (USA)

Qualifications

2nd class high-pressure gas machinery (August 14, 1992), Specified high-pressure gas chief engineer (March 25, 1992)

The Sustainable Development Goals established at the United Nations summit in 2015 as a global initiative to be achieved by 2030 have evolved into a global trend.

In 2020, the Japanese government pledged to work to achieve a carbon-free society by 2050.

Here, we talked to Project Professor Satoshi Uchida of the Energy and Environment Segawa Laboratory at The University of Tokyo Research Center for Advanced Science and Technology, who uses the AC-3 Photoemission Yield Spectrometer in research on next-generation solar cells, a field in which expectations are high both in Japan and worldwide.

So why are there such high expectations for next-generation solar cells as a key factor in achieving a carbon-free society?

Up until now, the use of natural energy has been tainted by negative connotations. One example: “Solar cells are unreliable because they depend on the weather and seasons.”

That’s completely wrong. The sun never rests. It’s unaffected by politics and economics, making it the most reliable energy resource.

However, the real problem with it lies not on the generating side, but in the storage of the electricity generated, which is where the conversation tends to get sidetracked. If the pumped storage generation of the nuclear power stations in Japan, which are currently out of service, was released for use in synch with natural energy like this, we could easily multiply the renewable energy usage rate for the country several-fold.

Research by scientists is vital in making natural energy a permanent part of society, but it’s also essential to get society as a whole, including government, experts, power companies, and businesses, to seriously consider how to use natural energy efficiently.

Next-generation solar cells not only offer higher power generating efficiency, they’re light and easy to install anywhere, which is why expectations are so high that they’ll help achieve a carbon-free society.

What exactly are the characteristics of the next-generation solar cells you study?

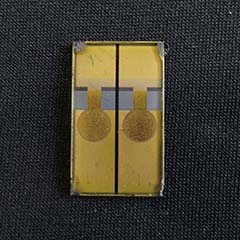

The Perovskite solar cell we’re currently working on was devised in 2009, and recent reports indicate they’ve achieved efficiency (η) exceeding 25 %. We’re currently in a head-to-head contest with monocrystalline silicon solar cells. This can be described as a major achievement, as until just a few years ago no one would have believed we could get performance like this from organic solar cells.

These Perovskite solar cells don’t require high-purity silicon semiconductors and can be fabricated by mixing conventional chemicals, but they also offer the major advantages of rapid manufacture using printing techniques and the ability to form products of large surface area.

Naturally there’s fierce competition underway around the world, and China in particular is making progress due to the tens of thousands of researchers it has recruited into the field. New reports indicate performance improvements not on a monthly basis, but weekly. The solar cell business in Japan, which once led the world, has seen a history of setbacks as well as technological outflow, which has brought the business into decline. Rather than remaining stuck in this rut, we’re seeking to achieve practical implementations that will allow the business to take the world by storm.

What does state-of-the-art science and technology have to offer society?

Health (longevity) and energy are inescapable and perennial issues for all human society.

To create a sustainable society, one of the goals of the SDGs, we’ll need to generate energy that doesn’t create environmental burdens and isn’t harmful to humans.

Solar power doesn’t deplete underground resources, doesn’t generate harmful gases, and unlike nuclear power doesn’t pose concerns about waste materials that can’t be processed or heat up seawater due to waste heat. From the standpoint of being able to use it with peace of mind, the expectations that solar power will contribute greatly to our daily lives are pretty high.

Can you give a rough idea of the timetable toward practical applications?

In his general policy speech at the end of last year, Prime Minister Suga said next-generation solar cells (Perovskite solar cells) were the key to achieving a green society. Following on from this, the government has provided funding of 2 trillion yen for decarbonization, and a project overseen by NEDO to put these solar cells to practical use is expected to get off the ground this year. Practical applications are scheduled to be achieved within a decade at the latest.

Can you describe how you first encountered the AC-3 and why you chose it?

I was interested in atmospheric photoelectron yield spectrometers from the relatively early stages. I believe the biggest advantage they offer is their ability to measure work function and ionization potential (IP) under atmospheric conditions. In 2001, we evaluated our samples using the AC-2. In 2007, I made a bold request and was kindly allowed to visit Riken Keiki to try out the AC-3.

Up until then, using a UPS was the norm for IP measurement. The system normally costs at least 100 million yen, and it wasn’t suitable for organic substances because measurements require a vacuum. There was also the issue of whether measurements obtained using such special conditions (vacuum conditions) truly reflected the characteristics of the material. While I’m likely repeating myself, I feel the AC-3 offers overwhelming advantages in allowing measurements under atmospheric conditions and being able to measure samples regardless of shape—even liquids!

What do you feel is the appeal of the AC-3 in actual use, and what do you hope to see from Riken Keiki?

This work function and ionization potential (IP) measuring system is a unique technology seen nowhere else. The fact that it’s been adopted by well-known major universities and research organizations worldwide backs this up.

Aside from the advantages offered by the system, we received extensive useful advice from Riken Keiki representatives on measurement procedures and analysis of the data obtained. Some of the results we obtained were jointly presented to bodies like the Japan Society of Applied Physics (JSAP), the Chemical Society of Japan (CSJ), and the US Materials Research Society (MRS), and the response was positive. We’re extremely grateful for the solid customer support we’ve received—it’s not the usual “thanks for your purchase, goodbye” attitude. From a user’s perspective, I hope to continue to cherish this deep relationship of trust into the future.

The needs of researchers are never-ending, such as “I need to measure band gap simultaneously”, “I need to measure while heating (or cooling)”, “I need to measure while irradiating under light, preferably monochromatic light”. [grins] But I have high expectations for Riken Keiki.

Could you give a few words of encouragement for our young researchers and future researchers?

In my case, I was influenced from a young age by my father, also a researcher, and I had vague dreams of one day being called “professor”.

After growing up and attaining the position of university lecturer, I felt strongly driven to specialize in another area in another university in a bid to escape my father’s influence, through ironically, after so many twists and turns I ultimately ended up in the same field, photochemistry. [Grins again]

I think the biggest reason for choosing life as a researcher is the amount of freedom one has in this field.

I feel there’s great value in devoting one’s life to substantiating ideas you’ve conceived yourself, as well the fundamental aspect of being useful to someone else as a result. Being in a neutral position as you are at a university, it’s really appealing to be able to come into contact with all kinds of people, regardless of company or country. No matter my age, this is what continues to stimulate and inspire me.

Both in the present and the past, I’ve been blessed with the people around me and the luck I’ve had, and feel I’ve led a life as a researcher that leaves nothing left to be desired. There are lots of things I’d like pass on to young researchers, but if I were to choose one I think it would have to be, “Don’t worry about how others assess you.” Everyone has weaknesses, and for better or worse, to succeed as a researcher in this world, you need a strong will and the ability to desensitize yourself. That will help you push ahead with your ideas. I’m sorry I can’t offer any more sensible advice, but that’s all I have.

In conclusion

According to Project Professor Uchida, while we’re still only midway to achieving practical application of next-generation solar cells, his firm belief that “the sun will shine forever, making it the safest and most reliable energy for mankind”, combined with his abundant inspiration, zeal, and perseverance, will undoubtedly accelerate work while creating unexpected treasures along the way.

Riken Keiki is proud to have helped Project Professor Uchida in his research.

Perovskite Solar Cell