In addition to protecting dielectrics from plasma, the MgO used as a protective film on plasma display panels generates and maintains the plasma by emitting electrons.

MgO, with its property of readily emitting electrons, reduces the voltage needed to generate plasma. This reduces loads on electrical circuits and cuts costs.

How readily MgO emits electrons depends on its surface state. While research is underway on various film forming and surface treatment methods, actually testing these in conjunction with panels is extremely costly and time-consuming. For these reasons, the AC Series is used as an easy solution for quantifying electron emissions in the form of the work function and count rates.

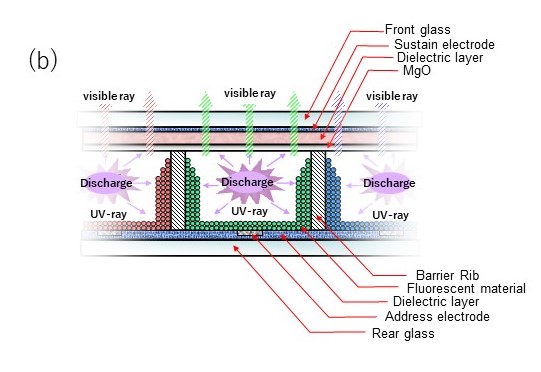

Fig. 1 Plasma display panel (PDP)

(a) Relationship between display and pixels (b) Pixel structure

Fig. 1 Plasma display panel (PDP)

(a) Relationship between display and pixels (b) Pixel structure

With PDPs, a discharge is produced inside the pixels. The UV light generated by the discharge excites the fluorescent material, producing visible light. The higher the secondary electron emission coefficient of the MgO, the lower the potential operating voltage. Many MgO films were created by different film forming and surface treatment methods in the PDP development lab. Playing a key role in finding ways to manufacture MgO films with high electron emissions, the AC Series was used to measure photoelectron emission rates.