Lead frame washing process management

Lead frame washing processes require the use of many washing tanks. However, in many cases, the standards for the extent to which washing is required are vague, resulting in overwashing.

Overwashing results in the excessive use of plant equipment and waste and the corresponding excessive operating costs .Drain water from washing can also pollute the environment.

Case studies in which the AC Series was used to review washing processes reveal use of excessive numbers of washing tanks, offering potential savings equating to several-fold the standard cost of the AC Series.

Fig.1 Structure of IC

ICs (integrated circuits) consist of chips and lead frames.

Fig.2 Lead frames

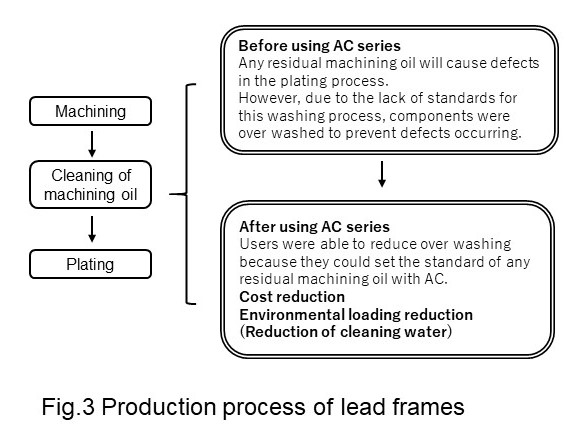

The lead frames are manufactured by the following process:

Fig.3 Production process of lead frames

Machining oil is used in the punching process. Any residual machining oil will cause defects in the plating process. This means the machining oil must be washed off. However, due to the lack of standards for this washing process, components were overwashed to prevent defects occurring.

As shown in Fig. 4, the AC measurement data shows a smaller slope for components with dirty surfaces and a greater slope for components with cleaner surfaces. In other words, surface contamination can be quantitatively managed based on this slope.

Fig.4 Measurement data of Lead frames

One manufacturer adopted cleaning based on this quantitative method to reduce overwashing, thus avoiding the use of unnecessary cleaning fluid and washing tanks.